-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how did you apply your mx-4 ?

- Thread starter shant

- Start date

- Joined

- Jan 4, 2009

- Location

- Brandon Mississippi

That's worth a shot too. Very very fine lines.

- Joined

- Sep 15, 2007

- Location

- Small town Emlenton, PA

Apply a thin bit, fill all the gaps. Use a CC card or such.

Buy another tube of MX-4, why not.

Put a blob in the middle, put in on, twist once back and forth, and put HS on tight with anal care to getting it even. Done.

Buy another tube of MX-4, why not.

Put a blob in the middle, put in on, twist once back and forth, and put HS on tight with anal care to getting it even. Done.

- Joined

- Aug 3, 2010

This is almost like surgery in here with applying thermal compound...

- Thread Starter

- #26

Apply a thin bit, fill all the gaps. Use a CC card or such.

Buy another tube of MX-4, why not.

Put a blob in the middle, put in on, twist once back and forth, and put HS on tight with anal care to getting it even. Done.

well the thing is, mx-4 isn't located here, and no one ships it either, luckily a friend got one for me,so yeah i better use this wisely

- Joined

- Apr 21, 2011

- Location

- Exton, Pennsylvania

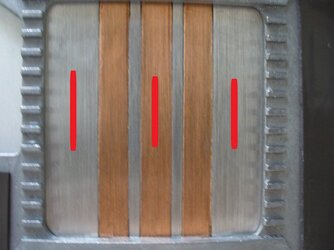

Wait, i dont see why you would put it somewhere that isnt a heatpipe. You want the best coating on the heatpipe, because the heatpipe transfers the heat, it should get the paste. This leaves the best thermal transfer where it needs to be and it will lower temps.

- Joined

- Apr 29, 2011

- Location

- Anchorage, Alaska

The key is that I have found with thermal stuffs, is that a little goes a loooong way

Edit: the main reason that the paste is in between the pipes on the picture above is because of the size of the gaps in between the heat pipes and the base. You don't really have a huge gap on yours so I wouldn't be so concerned about it. However, like Conumdrum said you can use a CC to smooth it out to fill the gaps leaving a thin layer over the whole apparatus

Edit: the main reason that the paste is in between the pipes on the picture above is because of the size of the gaps in between the heat pipes and the base. You don't really have a huge gap on yours so I wouldn't be so concerned about it. However, like Conumdrum said you can use a CC to smooth it out to fill the gaps leaving a thin layer over the whole apparatus

Tell me about it!This is almost like surgery in here with applying thermal compound...

Wait, i dont see why you would put it somewhere that isnt a heatpipe. You want the best coating on the heatpipe, because the heatpipe transfers the heat, it should get the paste. This leaves the best thermal transfer where it needs to be and it will lower temps.

The pics clearly show how the paste spreads after application.

You did see the pictures, right?

- Joined

- Aug 3, 2010

Look there is no reason to apply thermal compound to the aluminum part of the heat sink because the copper heat pipes are the only thing that helps out dissipate the majority of the heat.. So just apply 3 small lines on the copper heat pipes and then make sure that you have proper coverage like this...

Or just spread out a very thin coat and call it a day ... This is not rocket science and this way over complicated here guys for a basic thing here..

Or just spread out a very thin coat and call it a day ... This is not rocket science and this way over complicated here guys for a basic thing here..

Look there is no reason to apply thermal compound to the aluminum part of the heat sink because the copper heat pipes are the only thing that helps out dissipate the majority of the heat.. So just apply 3 small lines on the copper heat pipes and then make sure that you have proper coverage like this...

Or just spread out a very thin coat and call it a day ... This is not rocket science and this way over complicated here guys for a basic thing here..

I think this is the second time you've said this.

As you can see in the picture, the paste spreads to the pipes no matter where you put it but putting it on the aluminum gives you best coverage across the IHS. So why would you apply it any way other than the way that spreads the TIM to achieve the best coverage? Aluminum still dissipates heat and helps with cooling.

Also you can't say

You're contradicting yourself if you take into account that people fuss about 1 to 2* difference in temps.apply thermal compound to the aluminum part of the heat sink because the copper heat pipes are the only thing that helps out dissipate the majority of the heat..

To sum it up, putting the paste on the pipes doesn't mean you'll get the best temps while putting the paste on the aluminum STILL spreads the paste to the pipes and gives superior coverage. When both methods require same application procedure, just the location differs by few mm, why go with the method that was shown to spread the TIM across a smaller area?

Last edited:

- Joined

- Jul 16, 2001

On bigger chips like the GPU you're using, I usually spread TIM on the IHS with a straight edge.

That's how I've done it for years. I put a little on the IHS and spread with a straight edge. As thin as possible. As long as it covers completely and there isn't too much you are good. Too much can be just as bad (if not worse) than not enough.

As all others have said. A little goes a long way. I've used AS5 for many years. I've got like 4 tubes of it about 5 years ago. Those tiny little tubes have lasted me that long and I have 2 left.

- Joined

- Apr 29, 2011

- Location

- Anchorage, Alaska

http://www.arcticsilver.com/PDF/appmeth/amd/md/amd_app_method_middle_dot_v1.2.pdf

Check out the section on "tinting the heatsink"

Check out the section on "tinting the heatsink"

Similar threads

- Replies

- 26

- Views

- 5K