- Joined

- May 30, 2012

- Location

- California

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

But here's another set of figures from early 2010 from a French site that give very different numbers:Ok, so I just recalled that someone, which happened to be me, formally posted actual return rates for products from some PC company overseas. Clearly these numbers are not as accurate as the actual company's doa/return rates, however its likely much larger of a data set than LMCurly's personal experience...(not sure I buy that you have tested 1000 kits, personally).

I recall saying above:

Just so we are clear, the underlying meaning there is that is it worth it for you, LMC to insist to members, new members that are likely green behind the ears, to warrant buying a different brand/by IC's because: You assertions and general tone, LMC, lead me, new people you 'helped' and the rest of the participants in this thread, that there is a significant enough difference between brands that you should buy by IC to prevent RMAs. So without further musings by me.. I present the best set of facts we can get our hands on.

Source thread: http://www.overclockers.com/forums/showthread.php?t=717026&highlight=Failure

Quote:

- Crucial 0.23% (as against 0.4%)

- Kingston 0.40% (as against 0.5%)

- G.Skill 1.10% (as against 1.4%)

- Corsair 1.44% (as against 1.6%)

Crucial keeps top spot and, like the other manufacturers, improves its rate in a welcome overall downwards trend. Just two models have rates of over 5%, compared to 8 last year:

- 12.87% Corsair Dominator 4 GB (2x 2 GB) DDR3 1333 MHz CL9 - TW3X4G1333C9D

- 5.53% Corsair XMS2 2 GB DDR2 800 MHz CL5 – CM2X2048-6400C5

The worst Crucial model has a rate of 1.25%, the worst Kingston 2.1% and the worst G.Skill 3.14%.

What I take away from this is exactly what I said. There is ~1.2% difference between the best and worst vendors here with the worst vendor sporting a 98%+ success rate (not DOA or returned).

Another piece of information I thought you may find interesting LMC is all models combined and their return rates:

All ram combined that was sold by this company were not returned OVER 99% if the time WITHOUT KNOWING THE IC.

One other thing I would like to point out is Corsairs stunning 12.8% return rate on the dominator 4... LMC, did you notice those are 1333MHz sticks? I bet those IC's are actually rated for 1333MHz and are not 'overclocked' (though that is a guess). Wouldnt that right there bunk nearly all of which you are saying and at the same time support other's assertions that its simply a difference of failure rates regardless of IC? I think it does.

So I ask again, do you think its worth all the trouble/discussion over a MAXIMUM of 1.2% difference? Nobody in their right mind would think that is a significant value...significant enough to push a 'choose by IC or face the much higher potential of RMAing' agenda across multiple threads which only served to confuse the OP's. Again, you may have saved people from a MAXIMUM RMA possibility of 1.2% (best vs worse)... Congratulations.

- Kingston 0.30% (against 0.37%)

- Crucial 0.93% (against 0.78%)

- Corsair 1.41% (against 1.66%)

- G.Skill 2.73% (against 1.53%)

- OCZ 6.76% (against 2.76%)

- 15,08%: Corsair Dominator 2x2 Go DDR2 PC8500 CL5 - TWIN2X4096

- 11.28%: OCZ Value2x1 GB DDR2 PC2-6400 - OCZ2V8002GK

- 10.11%: G.Skill NQ Series 2x2 GB DDR3 PC3-10600 - F3-10666CL9D-4GBNQ

- 8.01%: G.Skill NT Series 2x2GB DDR3 PC3-10600 - F3-10600CL9D-4GBNT

- 7.19%: OCZ Gold Edition 2x2GB DDR2 PC2-6400 - OCZ2G8004GK

- 7.14%: G.Skill Ripjaws 2x2GB RM Series DDR3 PC3-10666 - F3-10666CL8D-4

- 6.65%: Corsair XMS3 2x2GB DDR3 PC10600 CL9 - TW3X4G1333C9

- 6.05%: OCZ Value2x1 GB DDR2 PC2-5300 - K-OCZ26672048VDC

- 5.88%: G.Skill HK Series 2x2 GB DDR3 PC3-10600 - F3-10600CL8D-4GBHK

- 5.65%: G.Skill Ripjaws 2x2GB HR Series DDR3 PC3-12800 - F3-12800CL7D

- 5.52%: Corsair XMS2 2x2GB DDR2 PC8500 CL5 - TWIN2X4096-8500C5C

- 5.16%: G.Skill 2x2GB DDR2 Standard Series PC2-6400 - F2-6400CL5D-4

- 5.15%: Corsair XMS2 2x2GB DDR2 PC6400 CL5 - TWIN2X4096-6400C5C

- 5.07%: Corsair DDR2 PC8500 CL5 Dominator2x1 Go - TWIN2X2048-8500C5D

The worst result is obtained by Crucial 4.37% of the Crucial Ballistix 2x1GB DDR2 PC8500 5-5-5-15 - BL2KIT12864AA106A while Kingston gets in the worst case 2.53% on a par ... 256 MB SDRAM!

I don't know JEDEC specs or the timings of the pulses or the differences beween 1333, 1600, and 1866, and the only thing I know about jitter is that it's not supposed to be too high, whether on a circuit board or through network cables, and the techs and engineers around here sure do like their instruments that can measure it.So can you tell me the JEDEC specs for DDR3? What is the JEDEC spec for for DDR3 1866?

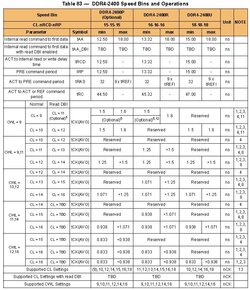

Did you know that 1333 and 1600 and all other DDR3 modules have the exact same Absolute clock HIGH pulse width and Absolute clock LOW pulse width?

Do you know what that is? What about jitter? Did you know the faster the memory the less jitter allowance?

Here are some specs:

Cumulative error across 2 cycles tERR(2per) - 147 147 - 132 132 - 118 118 - 103 103 ps

Cumulative error across 3 cycles tERR(3per) - 175 175 - 157 157 - 140 140 - 122 122 ps

Cumulative error across 4 cycles tERR(4per) - 194 194 - 175 175 - 155 155 - 136 136 ps

Cumulative error across 5 cycles tERR(5per) - 209 209 - 188 188 - 168 168 - 147 147 ps

Cumulative error across 6 cycles tERR(6per) - 222 222 - 200 200 - 177 177 - 155 155 ps

Cumulative error across 7 cycles tERR(7per) - 232 232 - 209 209 - 186 186 - 163 163 ps

But why do Micron, Samsung, and Hynix slap slower ratings on their chips than Kingston, Corsair, and G.Skill do for modules made of those very same chips,

But why do Micron, Samsung, and Hynix slap slower ratings on their chips than Kingston, Corsair, and G.Skill do for modules made of those very same chips,

Why would the chip makers have to spend 15x as much for labor if they became more aggressive with their chip speed ratings?Because its more profitable to get $3/chip (just an example) for 40-million chips and pay for 1-million man-hours worth of labor at $10/hr than it is to get $4/chip for 40-million chips and pay for 15-million man hours worth of labor at $10/hr. (all of these figures are massive examples but still represent how economics of owning a business work)

What's worrying about it? How will people hurt their computers or make them unreliabl by doing what I've recommended about computer memory -- there, here, or anywhere else, other than when I said running at absolute maximum voltage 1.975V wouldn't instantly blow up RAM chips? And I said that only because somebody thought 1.35V DRAM chips couldn't be run at the same voltage as 1.50V chips.Who are these said engineers? Say what?

I still don't get how you reply to that statistic like that, and Ive seen your posts at ocn (samsung green club thread)...it's a bit worrying to say the least.

Why would the chip makers have to spend 15x as much for labor if they became more aggressive with their chip speed ratings?

Because its more profitable to get $3/chip (just an example) for 40-million chips and pay for 1-million man-hours worth of labor at $10/hr than it is to get $4/chip for 40-million chips and pay for 15-million man hours worth of labor at $10/hr. (all of these figures are massive examples but still represent how economics of owning a business work)

I don't expect all examples to be totally realistic, but what does yours have to do at all with DRAM chip makers vs. module makers, regardless of the numbers of dollars or numbers of workers involved? I'm simply saying the chip makers aren't playing the same ratings hustle as the module makers are, and the failure rates I've experienced seem to bear this out.Its an example

If it was financially viable they would do it, since it is not they don't bother. (not to mention it is much easier to make memory to JDEC standards and let someone else upcharge for boutique memory).

Just for reference, LMC, this is 2013. A full two years after that was published. See the numbers the year before that (in parenthesis)? Much less. See the numbers the year before I posted the data? Much less as well (and was the full 2011 numbers I believe - as the ones I posted are 1H 2012). I believe that data you posted is from the same site I linked my information from. I also need to mention, nobody, today, gives a rats *** about DDR2. We are strictly talking DDR3 here so those numbers which seem to contain a lot more DDR2 than my entry, are not as valid in this context. Again, DDR3, 2013. Not DDR2 and 3, first part of 2010.But here's another set of figures from early 2010 from a French site that give very different numbers:

And in the last two days I've been chastized worse than ever by the engineers in some other forums -- for basically siding even slightly with y'all on the issues of overclocking and overvolting.

We can lead the horse to water...Even in the face of over 99% good sticks, apparently its still worth it to spread this garbage here at nearly every turn (and he just did it again!!!). Thankfully, until we are actually corrected with logic, sense, and factual information, the staff here has their eyes on this seed sowing at OCF. OCN though, have it over there...not my home.And to sum up what several different people have said over several different posts, why would the end user care if the two ratings are different? If it works at the module makers advertised timings error free, than it works. If not, you RMA it.

I don't know JEDEC specs or the timings of the pulses or the differences beween 1333, 1600, and 1866, and the only thing I know about jitter is that it's not supposed to be too high, whether on a circuit board or through network cables, and the techs and engineers around here sure do like their instruments that can measure it.

But why do Micron, Samsung, and Hynix slap slower ratings on their chips than Kingston, Corsair, and G.Skill do for modules made of those very same chips, and why do chip makers think that $2,000 memory testers aren't good enough for packaged chips?

What's worrying about it? How will people hurt their computers or make them unreliable by doing what I've recommended about computer memory -- there, here, or anywhere else, other than when I said running at absolute maximum voltage 1.975V wouldn't instantly blow up RAM chips? And I said that only because somebody thought 1.35V DRAM chips couldn't be run at the same voltage as 1.50V chips.

Lets set aside questions about the validity of numbers or even the validity of the credentials of LMC's 'engineers.'

I've known a lot of engineers in my life, i've known a few scientists as well. What LMC's engineers are stuck on makes perfect sense for an engineer to be stuck on. To an engineer who low tolerance and even lower failure rates are their game, buying a part that works as advertised, and built for the job advertised makes the most sense. It's how they're trained to think.

My father who made more high energy equipment (read: lasers) then i can shake a stick at (and the computer controls that went with it) in his basement drilled many of those same principles into my head growing up. However, unlike most engineers, he was a bit of a technician. As in he got his hands dirty and actually built the things he designed, something I'm willing to wager 95% of engineers never really do in their lives.

Sorry for rambling but i'm building up to the point. My father rarely had a problem using parts that would work for the job, but weren't built specifically for the job. This is the crux of the situation, and i think the argument here.

LMC's & LMC's enginers basically want their ram built for the specific use they're putting it to. That if they're going to put ddr3 1333, 1.5V, 9-9-9-27 latency ram into their PC, they want ram specifically built to that specification. Not some piece of 1086 ram overclocked to 1333. That would fit an engineer's low tolerance right part of the right job mindset to a tee.

The problem is, there are plenty of ram chips which come factory overclocked to higher specs then originally designed. These chips function perfectly reliably at those higher clocks, and perform identically to those chips specifically and factory fabricated for those clocks. Pretty much all of the technicians on this site (and that's what most of us are, technicians) see no problem using a chip of ram which will work reliably as advertized, regardless of wether it's been designed specifically for that task or not.

Will some of those chips fail? sure, that's why we return them, but the one thing I've not seen in this whole discussion is proof that the factory designed chips fail at a lower rate then the overclocked binned chips. Furthermore, even if we had numbers which revealed this fact, we would have one more consideration. How high are those failure rates on the chips? if we're talking about a difference of half a percentage point, then i doubt any of the technicians here would or should care. I'm pretty sure there would be general apathy to this "engineer's argument" around here short of some sort of significant statistical variance in reliability along the lines of 3-5%.

I mean think of the audience you have here LMC... myself for example, have and likely will use again, parts scavenged from junk yards for parts for his water cooling systems. I've seen boxes on this forum that were basically made of all duct tape... there are guys here dumping liquid nitrogen on their chips here... and others seriously wondering if aquarium water chillers would work in replacing their radiators on their water loops.

This audience is all technicians here. We do what works... and generally don't care where or what the part originally was from or for.