- Joined

- Aug 11, 2005

- Location

- southern california

i was hoping that wouldnt happen to you. Hydrodynamics are way out of my leageu. That i swhy i want to make an exact copy. of the interior.

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

Otter said:Hey, I've got a theory for you to test, Voigts. Does the impeller lean toward where the outlet joins the impeller chamber? If so, perhaps the opening from the chamber to the outlet, is too wide. It could be that in the original design, the water and walls help center the impeller, and in yours, the outlet side is too "soft". If it leans a different way every time, then maybe your whole chamber is too big, or perhaps a bit too deep.

Edit: LOL, you're ahead me.Good luck.

My pump has not run at all as yet...either in stock form or with the Radical head.Otter said:Any idea how long Clocker2's top has been in service and if he runs the pump 24/7?

Yeah, I see what you mean.voigts said:It leans towards the outlet which is what is telling me that is the problem.

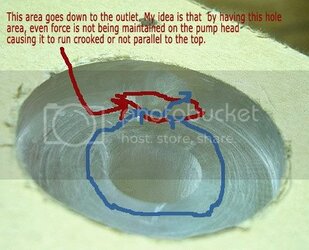

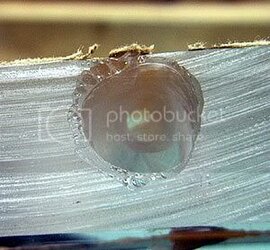

Here are a couple of pics to explain what I am thinking is my problem.

Otter said:Yeah, I see what you mean.

It's hard to tell in that pic, but it looks like you've got a channel leading almost all the way from the inlet to the outlet. Robotech reported slightly lower head after the mod and speculated it might be from increased leakage. This makes sense because with his mod you remove that little lip that extends down into (or almost into) the eye of the impeller, and that allows a wider path from the outlet side back to the inlet. It seems to me yours might have even more of this problem as it is now.

Oh yeah, it's not really tangential is it. I didn't notice that before. That might not be the source of the problem with the impeller, but I think it will be a problem for performance.DickH said:I noticed that the real pump top has the exit on the outside of the ring, and yours... isnt. Maybe that is the problem

Otter said:Oh yeah, it's not really tangential is it. I didn't notice that before. That might not be the source of the problem with the impeller, but I think it will be a problem for performance.

Voigts, are you going to start over or try to fix what you've got? Maybe you can fill in with epoxy or epoxy putty for a temporary fix, and then make a new top once you figure out how to do it right.

nachosyumm said:i dont think they cast them. Usually when stuff is cast it is much cheaper than a machined part. If they are casted, they must make a lot of profit on those tops.

I call revision 3!!! j/k

rev 4 looks really good. hopefully it works.