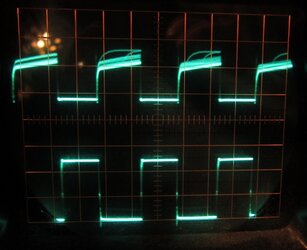

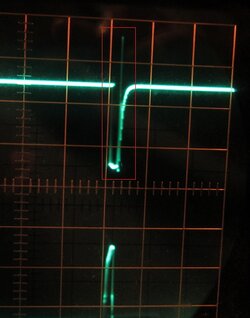

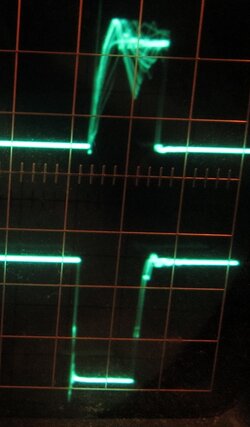

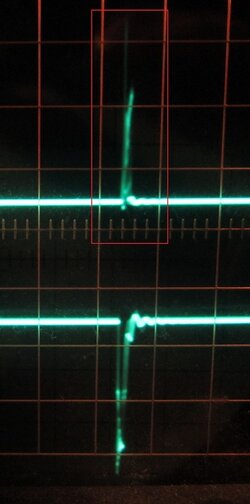

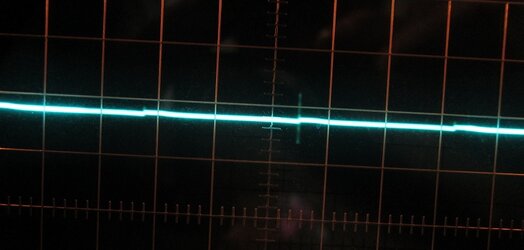

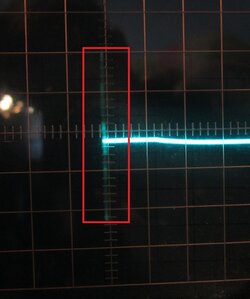

This demo show you how to achieve pwm control of any non-native PWM fans(normal 2-3 wire fans) using the PWM sensor from your MOBO.

This can be made for less than $4(In reality less than $1, i'm adjusting for people going to the over priced radio shack) for raw materials.

The soldering iron an such will cost more obviously.

...Um I didn't really didn't think about this till just now but I need to draw the schematic and screen shot it lol

It's super simple...I'll have it up when i find a circuit program to draw on, if not...i'll ghetto rig mspaint for people interested.

Notes:

- the Far right hand fan you can see is a PWM capable fan, but I'm not using the PWM wire to control it. This is why I kinda zoom to the fan connectors in the beginning to show that there is no pwm wire on the fans...just normal 2-3 wire fan. The sunon is a pure 2 wire fan.

- Excuse the hard breathing i was laying on the ground on my belly lolol

- Yes, I'm remoted into my computer using my iPad and using speedfan to control the pwm signal from the mobo.

Questions comments criticism...go

...One last thing, notice there is no strange wine or growl from these fans even when controlling them via PWM, 3 completely DIFFERENT fans

This can be made for less than $4(In reality less than $1, i'm adjusting for people going to the over priced radio shack) for raw materials.

The soldering iron an such will cost more obviously.

...Um I didn't really didn't think about this till just now but I need to draw the schematic and screen shot it lol

It's super simple...I'll have it up when i find a circuit program to draw on, if not...i'll ghetto rig mspaint for people interested.

Notes:

- the Far right hand fan you can see is a PWM capable fan, but I'm not using the PWM wire to control it. This is why I kinda zoom to the fan connectors in the beginning to show that there is no pwm wire on the fans...just normal 2-3 wire fan. The sunon is a pure 2 wire fan.

- Excuse the hard breathing i was laying on the ground on my belly lolol

- Yes, I'm remoted into my computer using my iPad and using speedfan to control the pwm signal from the mobo.

Questions comments criticism...go

...One last thing, notice there is no strange wine or growl from these fans even when controlling them via PWM, 3 completely DIFFERENT fans