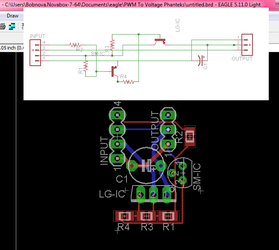

Pfft well that was more of a process than I though, Eagles is a bit cumbersome to use for the first time lol

Anyway:

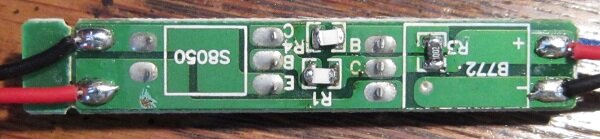

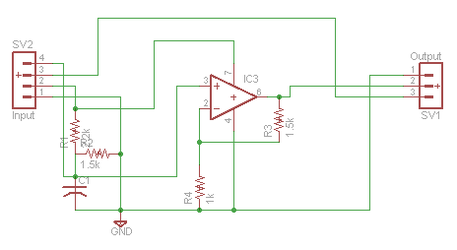

There are some calculations needed for the Darlington Pair, which is what the electronic world calls 2 npn transistors stacked one atop another.

We'll start with the specs of the fan:

V = 12v

I = .56amps

Calculations:

1. Know the amperage of your DC motor(s) this is what you are going to use to calculate the amount of current(I) needed to drive the OUTSIDE transistor. The outside being the transistor to the far right side.

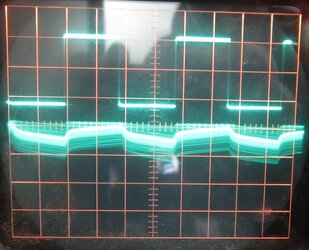

A transistor is used to control a very LARGE current, with a very SMALL current. In this case the large current would be the .56 amps of the motor, the small current would be the weak PWM signal from your mobo.

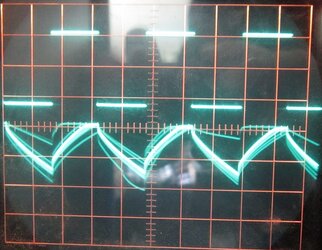

So how it works, the MORE current you give the (B)ase of the transistor the MORE current it will allow to flow from the (Collector) to the (E)mitter. It's like a water faucet at your house. You turn the knob(takes little force) to control the amount of water that goes through...same exact thing.

How do we find this "little force" that controls the big one? Simple, if your using a TIP31c transistor...just divide .56a by 100. = .0056a

What the hell is that for!? Well that right there(.0056a) is the MINIMUM amount of current you need to supply the (B)ase of the transistor to allow ALL .56amps to flow from (C)ollector to (E)mitter... In other words. If you supply the (B)ase with .0056amps, the transistor allows all teh current to flow though it so that you get FULL POWER.

Once you start lowering .0056a to the (B)ase the transistor starts restricting the current flow and hence your current and consequently voltage, starts to drop/go down/not flow as much.

STOP.

This is actually where most people can stop! Yup, that's it. All you REALLY NEED is a TIP31C NPN transistor and there you have it a PWM controllable fan(s) via your motherboard header.

In the above schematic remove the left transistor and resistor.

1. Feed the fans RED wire 12volts from the PSU(NOT the mobo)

2. Connect the fans black wire to the transistors (C)ollector.

3. Connect the (E)mitter to ground and finally feed the (B)ase of the transistor your PWM signal from your mobo.

*The reason we stop here is the fact that your fans draw is .56A(560mA, , milliAmps). You only need .0056A (5.6mA, milliAmps) to drive the transistor, which then drives the motor. Your motherboards headers can very much source 5mA if current without even breaking a sweat. Do you see now how a small current(5.6mA) can control a very large current(560mA).

The Darlington pair chops this number down even further(.0056 / 100 = .000056A)! So now you can control a GINORMOUS load(limited by how much current your transistor can handle from (C)ollector to (E)mitter) with a TINY amount of force.

That's as far as I'll go for now, if you want to know how to calculate and use the rest of the schematic, I'll explain if needed. Otherwise, the electrical engineering folks will recognize this Darlington Pair