- Joined

- Mar 27, 2011

- Location

- Soviet Mexico

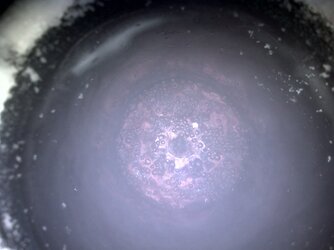

Okay so I promised pictures for some new members and just in general to those hanging out in the stream. I did a few things different From the norm.

So I got my KoolanceV2 today. Pulled it out of the box and got ready to freeze some hardware. I didn't use the stock Neoprene insulation. I noticed that it tends to suck up alot of water which is No Bueno. So I took outdoor pipe insulation (which is closed cell to a point and has a much larger amount of air then material which is good). I cut the Insulation to the heights that I needed then due to limited selection of diameter locally I just duck taped them together (duck tape sticks great to this stuff).

I made one small section for the top of the pot, above the tensioning backet. One for the bottom section of the pot, under the tensioning bracket down to the motherboard. Then I made a 3rd one to go over all of that. This worked great Only thing I am gonna change is to make sure that i have the ends which I have cut Sealed with either silicoln or tape. that way it doesn't suck up any water into the cells (the are large elongated cells that are one to two needle widths wide, and about 1inch or so long it seems). The tape thats in direct contact with the pot will sweat and cause frost, but the second layer of insulation around this minimized the heatloss to the sides by alot. My ghetto digitial thermometer only went as low as 14c on the outside of the outside layer of insulation, the paper towls never got wet.

I will post some more pictures tommarow and a more detailed guide on how i made the pieces. They're cheap and easy to make, just take time.

So I got my KoolanceV2 today. Pulled it out of the box and got ready to freeze some hardware. I didn't use the stock Neoprene insulation. I noticed that it tends to suck up alot of water which is No Bueno. So I took outdoor pipe insulation (which is closed cell to a point and has a much larger amount of air then material which is good). I cut the Insulation to the heights that I needed then due to limited selection of diameter locally I just duck taped them together (duck tape sticks great to this stuff).

I made one small section for the top of the pot, above the tensioning backet. One for the bottom section of the pot, under the tensioning bracket down to the motherboard. Then I made a 3rd one to go over all of that. This worked great Only thing I am gonna change is to make sure that i have the ends which I have cut Sealed with either silicoln or tape. that way it doesn't suck up any water into the cells (the are large elongated cells that are one to two needle widths wide, and about 1inch or so long it seems). The tape thats in direct contact with the pot will sweat and cause frost, but the second layer of insulation around this minimized the heatloss to the sides by alot. My ghetto digitial thermometer only went as low as 14c on the outside of the outside layer of insulation, the paper towls never got wet.

I will post some more pictures tommarow and a more detailed guide on how i made the pieces. They're cheap and easy to make, just take time.

Last edited: