-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official IC Perihelion Test Results Thread

- Thread starter JoeC

- Start date

- Thread Starter

- #23

Joe, the duct tape trick is something I learned with the original scissors type TRUE mount. As you know, the original mount had a bad problem holding the heatsink from rotating on top of the processor. I figured that it was due to the bracket having so little contact area between it and the top of the heatsink base. I put the tape originally to give a stickier than metal to metal contact patch between the top of the heatsink base and the scissors bracket and let the bracket "dig in", so to speak. And it works well in that regard. But I also noticed that I started getting lower load and idle temps after doing this too. When you add a strip of the duct tape across the top of the heatsink base (the part that the clamping bracket contacts on the base), the layer of tape also acts to thicken the base that the bracket has to clamp against, giving more clamping pressure. How much more I really can't tell you since I don't have the sophisticated equipment necessary to check the clamping pressure but it does increase it somewhat. And just to double check that the better temps weren't due solely to the heatsink not rotating on top of the processor when clamped, I carefully had mounted the TRUE without having any heatsink movement and ran a stress test, then did the duct tape trick and retested and saw a decrease in temps using the duct tape.

Ok, makes sense on the pressure aspect - The tape is wound around a corner/ edge allowing a harder pull when setting the tape? Do I have that right?

Seems like you would get a solid mount out it, the question is side to side pressure balance. I suppose it is kind of a feels right kind thing you get with practice?

I read somewhere that Alaskans use more duct tape per capita than anybody else. I figured it was a materials thing like when it is 20 below you grab whats handy rather then make the twenty mile trek to Home Depot or you are taping up doors, windows, cracks to keep the frost out of the bathroom

Last edited:

- Joined

- Nov 1, 2001

- Location

- New Iberia, LA

Joe, here are a couple of pics showing you the LGA775 mount that Thermalright is now using for the TRUE models that I am using for the tests and my application of the duct tape to the top of the base of the heatsink.

First, the new revision LGA775 TRUE mount:

And this is the top of the base of my original TRUE, that has had the duct tape mod done to it. This isn't the copper TRUE I am testing with, but shows how I similarly applied the duct tape to the top of the base. The crossbar of the mount lays across the base and presses down on the duct tape. The dimple in the middle of the crossbar just centers the heatsink and doesn't acutally apply more pressure, like the Venomous X mount does with the screw they added. Excuse both pics for being slightly out of focus, but they are good enough to show what I am talking about.

@ rge, my job in real life entails a lot of testing and for it to actually do any good at all, you have to eliminate or minimize as many variables as possible or the tests are meaningless. Once the variables are minimized, then you can attribute differences in readings to the variables you introduce into the test. And I have been interested in cooling for a long time and this gives me an excuse to play around. I just wish my cooling habit wasn't so expensive. I just bought around $150 worth of coolers in the last month or 2 for testing.

I just wish my cooling habit wasn't so expensive. I just bought around $150 worth of coolers in the last month or 2 for testing.

First, the new revision LGA775 TRUE mount:

And this is the top of the base of my original TRUE, that has had the duct tape mod done to it. This isn't the copper TRUE I am testing with, but shows how I similarly applied the duct tape to the top of the base. The crossbar of the mount lays across the base and presses down on the duct tape. The dimple in the middle of the crossbar just centers the heatsink and doesn't acutally apply more pressure, like the Venomous X mount does with the screw they added. Excuse both pics for being slightly out of focus, but they are good enough to show what I am talking about.

@ rge, my job in real life entails a lot of testing and for it to actually do any good at all, you have to eliminate or minimize as many variables as possible or the tests are meaningless. Once the variables are minimized, then you can attribute differences in readings to the variables you introduce into the test. And I have been interested in cooling for a long time and this gives me an excuse to play around.

Last edited:

- Joined

- Nov 20, 2007

- Location

- Fburg, VA

Now for my second set of results.

AMD Athlon 64x2 6000+ @ 3.3ghz 1.36v

Zalman CNPS 9700NT

Zalman STG1 (brush on liquid paste)

Ambient Temp: 20*c

Idle Temp:28*c

Load Temp:41*c

Heat Sink Fan Speed:2733rpm

IC Diamond pea sized blob

Ambient Temp:21*c

Idle Temp:29*c

Load Temp:42*c

Heat Sink Fan Speed:2733rpm

Perihelion pea sized blob

Ambient Temp:21*c

Idle Temp:29*c

Load Temp:44*c

Heat Sink Fan Speed:2733rpm

_________________________________________________

XFX 8600GTS XXX Edition

Zalman STG1 (brush on liquid paste)

Ambient Temp:21*c

Idle Temp:47*c

Load Temp:71*c

Heat Sink Fan Speed:100%

IC Diamond half pea blob

Ambient Temp: 21*c

Idle Temp:48*c

Load Temp:71*c

Heat Sink Fan Speed:100%

Perihelion half pea blob

Ambient Temp:21*c

Idle Temp:49*c

Load Temp:74*c

Heat Sink Fan Speed:100%

GPU tested using FurMark Xtreme Burn for 10 min cycles.

CPU tested the same method as my i7 tests.

AMD Athlon 64x2 6000+ @ 3.3ghz 1.36v

Zalman CNPS 9700NT

Zalman STG1 (brush on liquid paste)

Ambient Temp: 20*c

Idle Temp:28*c

Load Temp:41*c

Heat Sink Fan Speed:2733rpm

IC Diamond pea sized blob

Ambient Temp:21*c

Idle Temp:29*c

Load Temp:42*c

Heat Sink Fan Speed:2733rpm

Perihelion pea sized blob

Ambient Temp:21*c

Idle Temp:29*c

Load Temp:44*c

Heat Sink Fan Speed:2733rpm

_________________________________________________

XFX 8600GTS XXX Edition

Zalman STG1 (brush on liquid paste)

Ambient Temp:21*c

Idle Temp:47*c

Load Temp:71*c

Heat Sink Fan Speed:100%

IC Diamond half pea blob

Ambient Temp: 21*c

Idle Temp:48*c

Load Temp:71*c

Heat Sink Fan Speed:100%

Perihelion half pea blob

Ambient Temp:21*c

Idle Temp:49*c

Load Temp:74*c

Heat Sink Fan Speed:100%

GPU tested using FurMark Xtreme Burn for 10 min cycles.

CPU tested the same method as my i7 tests.

Last edited:

- Joined

- Nov 20, 2007

- Location

- Fburg, VA

- Joined

- Nov 1, 2001

- Location

- New Iberia, LA

I left the IC Diamond under load all night (BOINC/Rosetta) and this morning and then made one more Linpack run with OCCT to see what a 24 hour burn-in would do with the IC Diamond product. I listed the results above with the rest of my results for IC Diamond in post #14. I did see a slight but definite burn-in with the IC Diamond. I will remount the heatsink with the Perihelion product in a few moments and since I should be leaving for work tomorrow for 2-3 weeks I will let the sample run during that time running BOINC/Rosetta. When I come back in from work I will then re-run Linpack with OCCT and see what kind of temps I get then. That should give an idea of the long term effectiveness of the Perihelion product while in 24/7 use over the course of some weeks.

- Joined

- Jun 6, 2002

without thermal cycling of the tim, wont that effect the tims ability of heat transfer? that is i thought to make sure TIM "set" was to thermally cycle it. would a straight 24/7 load for 2-3wks really make no difference in thermally setting the tim?

- Joined

- Nov 1, 2001

- Location

- New Iberia, LA

I'll be here tonight and plan to do some thermal cycles this evening. And in my experience with tim like AS5 in the past, it will still show a break-in without cycling, but takes much longer for it to happen. But I should be able to get several thermal cycles in before I leave.

- Joined

- Nov 25, 2008

I hate every single thing related to the mounting system on this AC7, but I got the Q6600 running at 1.5v load now with AS5. All goes well I'll swap out for the new stuff when I wake up tomorrow morning.

Oh, running P95 and furmark simultaneously. I think I might wake up to my PSU on fire or something.

EDIT: Have to run blend with P95, the others just get too hot (80c+) and crash out after <15 min.

Oh, running P95 and furmark simultaneously. I think I might wake up to my PSU on fire or something.

EDIT: Have to run blend with P95, the others just get too hot (80c+) and crash out after <15 min.

Last edited:

- Thread Starter

- #34

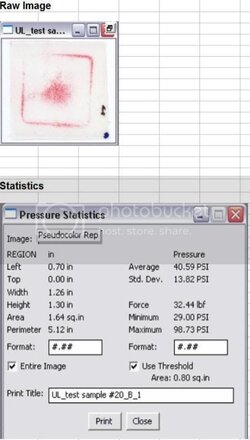

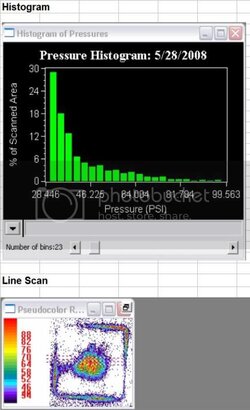

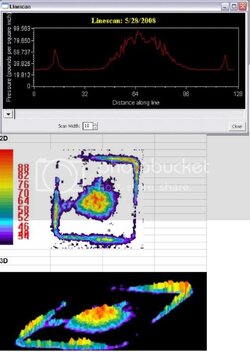

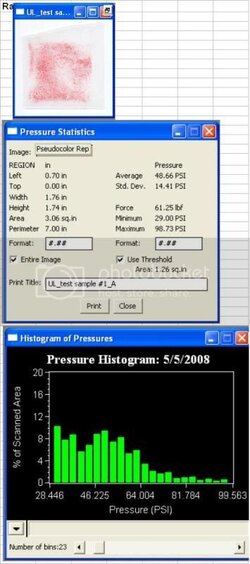

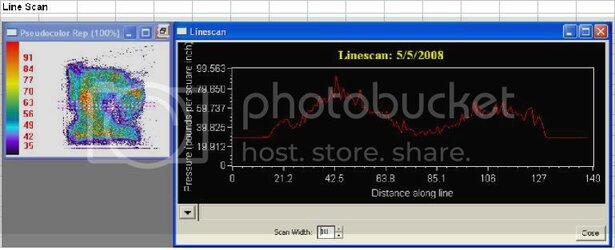

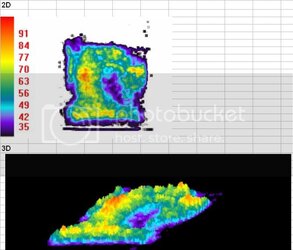

Paste Patterns are great indicators of contact and pressure quality. This IHS was unlapped and had an "island in a lake" kind of a pattern only making contact in the center and edges

Here is the digital analysis. almost 100 psi on center with 60 psi on the edges. Area on center with thin glaze is representative of good contact. Thicker paste spread indicate light contact and/or light pressure. upper and lower threshhold 28psi and 99 psi

This is the best contact out of about 45 samples that were done I am still looking for the raw paste image to go along with it.

Here is the digital analysis. almost 100 psi on center with 60 psi on the edges. Area on center with thin glaze is representative of good contact. Thicker paste spread indicate light contact and/or light pressure. upper and lower threshhold 28psi and 99 psi

This is the best contact out of about 45 samples that were done I am still looking for the raw paste image to go along with it.

Last edited:

- Joined

- Nov 25, 2008

First batch of temps in, perihelion next.

Q6600 3.4ghz (normally 3.6 but it's not stable enough aparrently ) and 1.5v (about 1.48-1.49 under load). Somewhat cooled by an AC7 with my patented bolt through system and some old fan from a dell.

) and 1.5v (about 1.48-1.49 under load). Somewhat cooled by an AC7 with my patented bolt through system and some old fan from a dell.

Pre-Perihelion

Compound:AS5

Ambient Temp:26c

Idle Temp:48-50c

Load Temp:80-82c

Heat Sink Fan Speed:100%

Perihelion

Ambient Temp:

Idle Temp:

Load Temp:

Heat Sink Fan Speed:

Radeon 4870, stock volts, reference cooler.

Pre-Perihelion

Compound:????? Stock paste

Ambient Temp:26c

Idle Temp:49-50c

Load Temp:65-67c

Heat Sink Fan Speed:100% (Noisy!)

Perihelion

Ambient Temp:26c

Idle Temp:42c-43c

Load Temp:64-65c

Heat Sink Fan Speed:100%

Preliminary tests with the perihelion on the 4870 show idle temps around 41c, load is about 61-62c. This was only in a 4 or so min run, I'll have proper results tomorrow.

Also, I hate the screws on the 4870, I was trying some multi tool to get them out and it snapped back and crushed some random transistor on the back of the board. Luckily everything seems to still run fine....

EDIT 3: Updated 4870 temps, gonna swap out the Q6600 today.

Q6600 3.4ghz (normally 3.6 but it's not stable enough aparrently

) and 1.5v (about 1.48-1.49 under load). Somewhat cooled by an AC7 with my patented bolt through system and some old fan from a dell.

) and 1.5v (about 1.48-1.49 under load). Somewhat cooled by an AC7 with my patented bolt through system and some old fan from a dell.Pre-Perihelion

Compound:AS5

Ambient Temp:26c

Idle Temp:48-50c

Load Temp:80-82c

Heat Sink Fan Speed:100%

Perihelion

Ambient Temp:

Idle Temp:

Load Temp:

Heat Sink Fan Speed:

Radeon 4870, stock volts, reference cooler.

Pre-Perihelion

Compound:

Ambient Temp:26c

Idle Temp:49-50c

Load Temp:65-67c

Heat Sink Fan Speed:100% (Noisy!)

Perihelion

Ambient Temp:26c

Idle Temp:42c-43c

Load Temp:64-65c

Heat Sink Fan Speed:100%

Preliminary tests with the perihelion on the 4870 show idle temps around 41c, load is about 61-62c. This was only in a 4 or so min run, I'll have proper results tomorrow.

Also, I hate the screws on the 4870, I was trying some multi tool to get them out and it snapped back and crushed some random transistor on the back of the board. Luckily everything seems to still run fine....

EDIT 3: Updated 4870 temps, gonna swap out the Q6600 today.

Last edited:

- Joined

- May 10, 2009

Ok, finally got around to installing ICD7, i don't have the temp gun at my house so i don't have ambients.

It was a large blob method, and spread much better then the smaller blob, but it looks like i didn't bring the cooler down perfectly flat so it was lopsided, and the layer was rather thick.

In any case, it had these temps:

Idle 22/21

IBT 67/68

(Interestingly, this is a lower idle and a higher load then the previous testing of this same mount, it idled at 24/23 and IBTd at 63/63)

ICD7, applied with my line-o-dots down the heatpipes and dividers method:

Idle 21/20

IBT 55/55

Hell of a difference there. I found the ICD7 easier to work with as well, largely because it is a bit stickier, so it's much easier to make little piles without the whole pile sticking to the syringe and getting pulled off the CPU.

It was a large blob method, and spread much better then the smaller blob, but it looks like i didn't bring the cooler down perfectly flat so it was lopsided, and the layer was rather thick.

In any case, it had these temps:

Idle 22/21

IBT 67/68

(Interestingly, this is a lower idle and a higher load then the previous testing of this same mount, it idled at 24/23 and IBTd at 63/63)

ICD7, applied with my line-o-dots down the heatpipes and dividers method:

Idle 21/20

IBT 55/55

Hell of a difference there. I found the ICD7 easier to work with as well, largely because it is a bit stickier, so it's much easier to make little piles without the whole pile sticking to the syringe and getting pulled off the CPU.

- Joined

- Aug 11, 2008

Test Setup

E8400 E0 @ Stock 9x333MHz (Lapped grits: 600, 800, 1000)

Xigmatek HDT-s1283 w/ Bolt-Thru (Lapped grits: 1000)

1xPush Panaflo FBA12G12H 103.8ft^3/min

Methodology

- Since I have a HDT heatsink, I filled in the gaps between heatpipes before using your standard 5.5mm dot method. Filling heatsink gaps and 5.5mm dot was the method used on all compounds, whether it's the best method or not.

- Load testing was done with IntelBurnTest (Standard, 5 runs).

- 5 different vCores (listed below) were tested to check performance at higher temps.

Notes:

- The temps correspond to vCores: 1.154v, 1.200v, 1.248v, 1.296v, 1.344v (Tried to get 0.050v increments, turned out to be 0.048v).

- My sensors will not read lower than 37C.

Results

______________________________

Compound: None (That's right, none. I didn't even fill in the gaps between heatpipes.)

Ambient: 23C

Idle: 37, 37, 37, 37, 38

Load: 48, 54, 61, 70, 83

Fan Speed: 100%

Contact: -

______________________________

Compound: IC Perihelion

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 48, 52, 57, 65, 74

Fan Speed: 100%

Contact:

______________________________

Compound: IC Diamond

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 44, 49, 54, 61, 69

Fan Speed: 100%

Contact:

______________________________

Compound: AS Ceramique

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 45, 49, 55, 62, 71

Fan Speed: 100%

Contact:

______________________________

Compound: AS5

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 46, 50, 55, 62, 71

Fan Speed: 100%

Contact:

______________________________

E8400 E0 @ Stock 9x333MHz (Lapped grits: 600, 800, 1000)

Xigmatek HDT-s1283 w/ Bolt-Thru (Lapped grits: 1000)

1xPush Panaflo FBA12G12H 103.8ft^3/min

Methodology

- Since I have a HDT heatsink, I filled in the gaps between heatpipes before using your standard 5.5mm dot method. Filling heatsink gaps and 5.5mm dot was the method used on all compounds, whether it's the best method or not.

- Load testing was done with IntelBurnTest (Standard, 5 runs).

- 5 different vCores (listed below) were tested to check performance at higher temps.

Notes:

- The temps correspond to vCores: 1.154v, 1.200v, 1.248v, 1.296v, 1.344v (Tried to get 0.050v increments, turned out to be 0.048v).

- My sensors will not read lower than 37C.

Results

______________________________

Compound: None (That's right, none. I didn't even fill in the gaps between heatpipes.)

Ambient: 23C

Idle: 37, 37, 37, 37, 38

Load: 48, 54, 61, 70, 83

Fan Speed: 100%

Contact: -

______________________________

Compound: IC Perihelion

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 48, 52, 57, 65, 74

Fan Speed: 100%

Contact:

______________________________

Compound: IC Diamond

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 44, 49, 54, 61, 69

Fan Speed: 100%

Contact:

______________________________

Compound: AS Ceramique

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 45, 49, 55, 62, 71

Fan Speed: 100%

Contact:

______________________________

Compound: AS5

Ambient: 23C

Idle: 37, 37, 37, 37, 37

Load: 46, 50, 55, 62, 71

Fan Speed: 100%

Contact:

______________________________

Last edited:

- Joined

- Aug 11, 2008

I participated in the OCF IC7 tests, where can I get this new Perihelion TIM?

A few threads down: Innovation Cooling Giveaway - Perihelion Thermal Compound

JoeC is taking the first 100 members that post and agree to test.

Similar threads

- Replies

- 41

- Views

- 1K