- Joined

- Jul 14, 2004

- Location

- westminster, CO

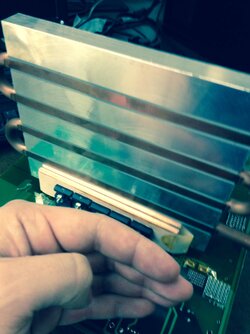

So I'm working on a summer project constructing a cooling system to dissipate 1.8 kW of heat put out by 16 rows of transistors. The chips themselves only need to stay under 100C but my goal is staying within 50-60C to simulate real world conditions. There will be 8 cold plates in series being used.

The cold plates to be used are the 4-pass plates:

http://www.aavid.com/sites/default/...pdf/liquid-cold-plate-datasheet-hicontact.pdf

Some friends working on the same project wanted to order this for the heat exchanging unit:

http://www.digikey.com/catalog/en/partgroup/wl-series/36412

I'm thinking it would be cheaper and easier to upgrade to handle more cooling capacity in the future if I just put together like 3-4 120.4 radiators and 2-3 pumps. I have an 800 watt power supply laying around that would work perfectly for this build. The piping will be entirely 3/8" copper tubing. The total length of the system tubing should be under 20-30ft.

Any thoughts on the viability of this? I would love to hear any input. I feel that the raddage will be more than enough. The only thing that really worries me is if 2-3 watercooling pumps will be enough to feed all 8 cold plates in series. These blocks are different then standard water-cooling hardware but I feel like they would be less restrictive.

The cold plates to be used are the 4-pass plates:

http://www.aavid.com/sites/default/...pdf/liquid-cold-plate-datasheet-hicontact.pdf

Some friends working on the same project wanted to order this for the heat exchanging unit:

http://www.digikey.com/catalog/en/partgroup/wl-series/36412

I'm thinking it would be cheaper and easier to upgrade to handle more cooling capacity in the future if I just put together like 3-4 120.4 radiators and 2-3 pumps. I have an 800 watt power supply laying around that would work perfectly for this build. The piping will be entirely 3/8" copper tubing. The total length of the system tubing should be under 20-30ft.

Any thoughts on the viability of this? I would love to hear any input. I feel that the raddage will be more than enough. The only thing that really worries me is if 2-3 watercooling pumps will be enough to feed all 8 cold plates in series. These blocks are different then standard water-cooling hardware but I feel like they would be less restrictive.