That's an interesting concept, I have some metal plate at that shop I could use to make a stiffening plate.

Post pic of the plate once you've made it will ya.

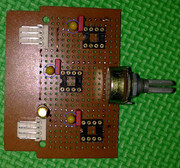

On a side note I made things super compact in case I wanted to stuff an attiny85 and digi-pot in on the other side there. I may still do it, but I need to test the digipot and see if it'll go low enough resistance wise to trigger full stop on the fan.

Just an idea Bob, once you've figured out the exact pot's adjustment where the fan stopped rotating, mark it down at your firmware and if still there is spare in port at your arduino, make it the 3rd button that if pushed, your firmware will jump to that exact adjustment point to stop the fan rather than keep holding/clicking the down button. This should be easy to code at your firmware and will be really handy.

I built the controller again at breadboard specifically to test the Nidec fan which is the same as Bob's. I tried it with a selection of pF caps (270-680) to change the PWM frequency but the fan wouldn't stop at low duty cycle. Out of interest Bob, what PWM frequency are you using for the Nidec fan?

It's not got that annoying high pitch squeal that the San Ace fans have, but at lowest rpm the fan motor is pretty loud and too annoying for daily use.

It's interesting that my PWM controllers/fans always behave differently from the ones that other members are using! WHAT GIVES!!

Yeah, prolly your diy circuits are cursed LOL

... j/k

Seriously, I begin to suspect the psu is the culprit behind all your weird experience with this circuit, have you tried with other power source ?

Also re-check again your ground lane, the fan's and the circuit's ground wires should be solidly connected, if they're connected by twisted two wires, solder it, cause sometimes this kind of poor connection will create weird problems that could make even a senior EE will scratch his head for quite sometimes if they didn't aware of it.

Hey inVain,

to OcF !! Btw, he is the one who made this circuit at our local community here in Indonesia.

Selamat bergabung, tumben bisa terdampar disini ? Yep, saya bvi di kampung halaman !

That is a great implementation, btw, show us the other shot that its mounted at the pci slot, this should inspire others.

Btw, glad you've bought that delta, I see you finally grabbed one of this monster at chip classy, glad to hear this.

About the wrong adjustment direction, as Bob said, just swap those 2 outer pot's pins, from that pic even I can't see it the solder side, this should be easy by moving or crossing the 2 wires that are soldered at the pot's pins at the pcb side.

to OcF !! Btw, he is the one who made this circuit at our local community here in Indonesia.

to OcF !! Btw, he is the one who made this circuit at our local community here in Indonesia.