Good afternoon folks of overclockers forum.

I'm going to do my first complete build in a decade, and just had a few questions.

I have a Laing pump with tens of thousands of hours in it in my old system. I've noticed these pumps have almost doubled in cost since I bought it. Can I just buy a replacement motor for the pump and reuse the part with the impeller/barbs and such?

Does anyone have a recommendation for how to setup a fill and drain port? I have seen these clean looking EKWB ports that open with a hex key, but it looks like I have to be able to tap a g1/4 thread into the case, which I can't do (as opposed to just drilling a hole).

Do you think I can safely reuse the old PSU? I think is only about 5 years old, but my whole deal is to build a "platform" of long-lasting parts so I can upgrade the rest of the hardware (CPU GPU and such) several times over.

Here's a pic of the old ugly system, circa 2010. Its an Antec 900 with a Bronco heater core (about 8" x 8") on the top 200mm and a 120mm PC radiator on the rear. I've upgraded the hardware every couple of years, and its about time to make something cleaner looking.

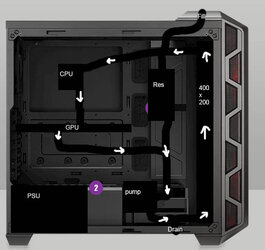

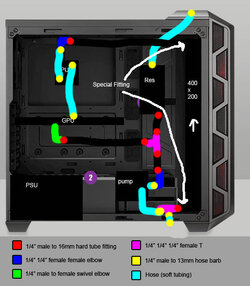

The new build is going to be a CM H500 with a front-mounted 16"x8" radiator from a suzuki bandit 650. Im going to keep all the parts internal so it looks neat.

Thanks all for any advice and perspective.

I'm going to do my first complete build in a decade, and just had a few questions.

I have a Laing pump with tens of thousands of hours in it in my old system. I've noticed these pumps have almost doubled in cost since I bought it. Can I just buy a replacement motor for the pump and reuse the part with the impeller/barbs and such?

Does anyone have a recommendation for how to setup a fill and drain port? I have seen these clean looking EKWB ports that open with a hex key, but it looks like I have to be able to tap a g1/4 thread into the case, which I can't do (as opposed to just drilling a hole).

Do you think I can safely reuse the old PSU? I think is only about 5 years old, but my whole deal is to build a "platform" of long-lasting parts so I can upgrade the rest of the hardware (CPU GPU and such) several times over.

Here's a pic of the old ugly system, circa 2010. Its an Antec 900 with a Bronco heater core (about 8" x 8") on the top 200mm and a 120mm PC radiator on the rear. I've upgraded the hardware every couple of years, and its about time to make something cleaner looking.

The new build is going to be a CM H500 with a front-mounted 16"x8" radiator from a suzuki bandit 650. Im going to keep all the parts internal so it looks neat.

Thanks all for any advice and perspective.

Last edited: