- Joined

- Jan 12, 2012

Clever idea with the rod to make sure the valves don't mysteriously open on their own.

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

Mobo comes that color.Did you spray Mobo black? How did you get it clean around capacitors?

I mentioned silver solder on the previous page, but it occurs to me the biocide effect of silver makes silver solder an attractive choice. What solder are you using for the copper, if I may ask?

Problem with the silver is it needs to be easy hotter to solder compared to the lead free. 188*C compared to 420*C for silver. I'll do some test joints and see if it discolors the copper.I mentioned silver solder on the previous page, but it occurs to me the biocide effect of silver makes silver solder an attractive choice. What solder are you using for the copper, if I may ask?

I have no idea if copper is antimicrobial, but that would be optimal as all get out.Isn't the copper piping already a natural antimicrobial?

Are you going to use radiator? Seems like 3 miles of copper and 600lb steel desk is enough to dissipate half a dozen GHz easy..

Sweet. That should mean I can push 9ghz on my i9 7980!Are you going to use radiator? Seems like 3 miles of copper and 600lb steel desk is enough to dissipate half a dozen GHz easy..

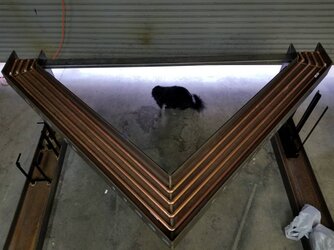

Haha I am thinking about how to use the frame as a passive cooling system along with the radiators. I'll do some testing this weekend.I was thinking the same thing! Regularly spaced spots of silver solder securing the tubing to the I-beams may do a fine job of dissipation! Then again, this build is all about excess.