- Joined

- Dec 13, 2003

- Location

- Tempe Desert

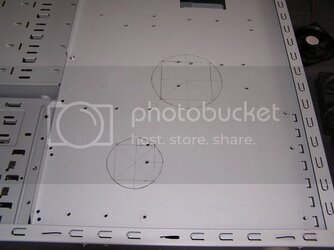

Ok, I have recently upgraded my case to a Cooler Master Cavalier 3 SEEN HERE

I'm not gonna list all my mods right now because there are a lot and I'm still not sure if all will become a reality so that's why this is a running thread that I will update as each new mod has been started or completed.

Ok, well let's kick this biotch off!!

First task was to strip this thing of all its cloths and dignity! HAHA

I'm not gonna list all my mods right now because there are a lot and I'm still not sure if all will become a reality so that's why this is a running thread that I will update as each new mod has been started or completed.

Ok, well let's kick this biotch off!!

First task was to strip this thing of all its cloths and dignity! HAHA

Last edited: