- Joined

- Dec 7, 2003

Brass Tacks: One Day Scratch Build

In colloquial English, Brass tacks (often "get down to brass tacks") refers to the fundamental or essential elements of a topic.

(wikipedia)

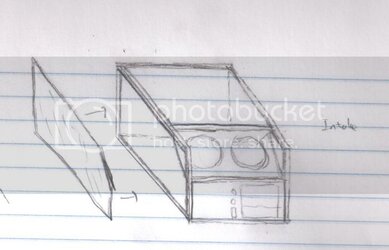

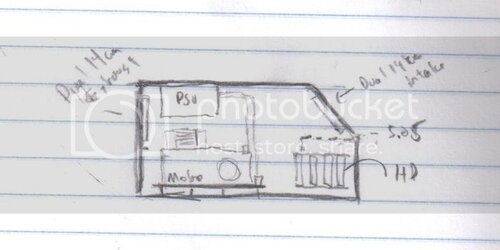

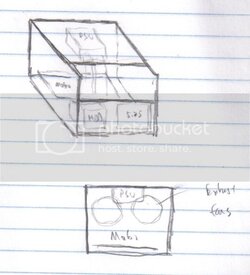

I’m putting together my next scratch build, and I am going to attempt to build it in one single day.

Its going to be pretty basic build, with minimal finish. The base framework is based on my exoframe, but I’m going to simplify the plastic paneling by just flush-mounting it instead of inset mounting them.

I’m planning for Monday or Tuesday.

But the next few posts, I’m going to lay out all my planning.

First of all, a single day may be a little ambitious, but I am starting with my DIY corner brackets already pre-made.

DIY Inside corner bracket thread.

If you read thru the post,

1) This is the project I was referring to when I first put the brackets together

2) I also mention that while you could easily powdercoat the brackets, I was going to leave them unfinished brass for this project.

That is why I’m titling this project Brass Tacks: I’m going to be using a lot of unfinished/raw brass and metal as part of this build to simplify the look and make it possible to complete in one day (hopefully).

.

In colloquial English, Brass tacks (often "get down to brass tacks") refers to the fundamental or essential elements of a topic.

(wikipedia)

I’m putting together my next scratch build, and I am going to attempt to build it in one single day.

Its going to be pretty basic build, with minimal finish. The base framework is based on my exoframe, but I’m going to simplify the plastic paneling by just flush-mounting it instead of inset mounting them.

I’m planning for Monday or Tuesday.

But the next few posts, I’m going to lay out all my planning.

First of all, a single day may be a little ambitious, but I am starting with my DIY corner brackets already pre-made.

DIY Inside corner bracket thread.

If you read thru the post,

1) This is the project I was referring to when I first put the brackets together

2) I also mention that while you could easily powdercoat the brackets, I was going to leave them unfinished brass for this project.

That is why I’m titling this project Brass Tacks: I’m going to be using a lot of unfinished/raw brass and metal as part of this build to simplify the look and make it possible to complete in one day (hopefully).

.