- Joined

- Apr 3, 2004

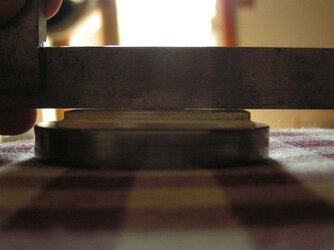

might need to find some 2200 0r 2500 grit  good luck ! I'm about to start on my g5 very soon

good luck ! I'm about to start on my g5 very soon

good luck ! I'm about to start on my g5 very soon

good luck ! I'm about to start on my g5 very soon Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

good luck ! I'm about to start on my g5 very soon

good luck ! I'm about to start on my g5 very soon

to the forums Xylo !!

to the forums Xylo !!