- Joined

- Apr 22, 2020

- Location

- Caprona

As a mad scientist, I have experimented with many different heat removal systems. Apparently, with Intel and AMD engaged in a little "heat war," where Intel can only outperform AMD with higher overclocks, even a triple radiator can't quite keep up if you are running all 8 cores of an i9-9900KS at something like 5.2 GHz.

A new type of heat removal was needed, since boiling water in a radiator won't be cooled sufficiently, even with 6 foot tall fans from the Boeing Wind Tunnel.

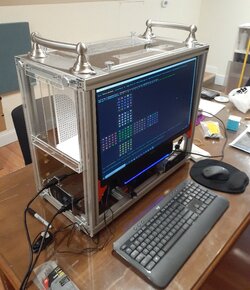

So here is my mock up solution, perhaps a little extreme:

The cold plate is solid copper.

The fins in the condenser (no radiator, vapor flows through it, not water) are also copper.

Copper has the wonderful property of having nearly twice the thermal conductivity as aluminum. That basically means you get the cooling performance as if you had twice as much surface area in the fins when compared to aluminum. Even still, I went with a huge condenser. It's the length of my elbow to my wrist.

I ordered two high speed fans that were BIG, as you can see. They can hit 5000 RPM with no problem. Of course, the pressure drop across the fins creates about 65 db of noise, far too loud to be practical. I will look to replace them with smaller fans, possible 4 of them in push-only configuration. The lower fan speeds x more fans should be able to deliver the same cubic feet per minute I require.

I use a very volatile cocktail of refrigerants so that they turn to vapor upon striking the cold plate. This vapor phase change is very endothermic. It produces fantastic temperatures even running Prime95 on all 8 cores 24x7 at 5.2 GHz.

I will show some more crazy builds and some build logs in the future. I also design my own custom cases, which you probably could tell.

A new type of heat removal was needed, since boiling water in a radiator won't be cooled sufficiently, even with 6 foot tall fans from the Boeing Wind Tunnel.

So here is my mock up solution, perhaps a little extreme:

The cold plate is solid copper.

The fins in the condenser (no radiator, vapor flows through it, not water) are also copper.

Copper has the wonderful property of having nearly twice the thermal conductivity as aluminum. That basically means you get the cooling performance as if you had twice as much surface area in the fins when compared to aluminum. Even still, I went with a huge condenser. It's the length of my elbow to my wrist.

I ordered two high speed fans that were BIG, as you can see. They can hit 5000 RPM with no problem. Of course, the pressure drop across the fins creates about 65 db of noise, far too loud to be practical. I will look to replace them with smaller fans, possible 4 of them in push-only configuration. The lower fan speeds x more fans should be able to deliver the same cubic feet per minute I require.

I use a very volatile cocktail of refrigerants so that they turn to vapor upon striking the cold plate. This vapor phase change is very endothermic. It produces fantastic temperatures even running Prime95 on all 8 cores 24x7 at 5.2 GHz.

I will show some more crazy builds and some build logs in the future. I also design my own custom cases, which you probably could tell.