Intel said Intel sales are high.

Stock price went from 23 something last year to 27 this year?

I assume you meant sales but I can understand the difference when listening to PR pieces. (Not a bust on you just an attempt at humour)

Little confused by your link.

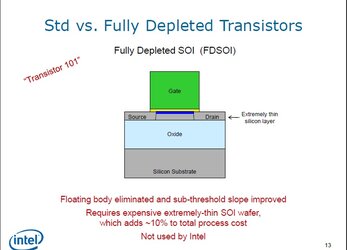

fully depleted silcon is too expensive "we dont use that" according to the PDF. Yet 2-3 panels later... trigate technology relies on fully Depleted silicon.

So they DINT use it, but now they do.. why obfuscate? I hate PR pieces.

Anywho.. Yes I see your point about reduction of size introducing new costs, however thanks to inflation, R&D costs go up regardless of die shrink. IB launched at only what 10-20 bucks more than most places were selling SB for?

One must consider the ethereal quality of PC component prices when considering costs. Not only space but time. CPUS used to cost thousands of dollars. Now they are a few hundred at most unless you are going nutty. Despite R&D costs going up because of inflation, despite component cost going up because of inflation. IB is still cheaper than SB was based on SB launch prices. Right?

Why is that? Despite the R&D (a cost of doing PC business) despite the component cost, (actually incremental when you consider the amount of each material being used per chip) you still get an extra XX chips per wafer.

http://www.anandtech.com/show/5789/the-ipad-24-review-32nm-a5-tested/

talking about ipad CPUs, but emphasizes the point in which he does also talk about. Couldn't find a good scale method but 45nm to 32nm hones in the point. Wafers are round. smaller the chip the more you can fit on it. (Why are wafers round why not square?)

45nm wafers produce 579 chips. 32nm 1019. Same cost of materials going in. almost twice that coming out.

You can increase cost and still come out even with a die shrink. Up to a 75% increase actually from 45nm to 32nm....) So yes.. the end users point of die shrink = lower cost is valid.

I wont go into details, but a 75% production increase even skewing it with a increased failure rate, and increase material base, still makes money.

Now all of a sudden Intel is an altruistic company that sells Ivy Bridge at a loss because it sucks? OF course they are making money, their stocks show it. IT fluctuates sure, but it is a currently volatile market and a company is not solely what its stock price is I get that.

Back to AMD though a company that ALSO does not sell things at a loss to improve market share. But does sell defective product in the hopes that people will buy them and try and unlock them into quasi function units. No warranty needed or provided. Saves a few hundred mill.

Neat idea..

EDIT: Sorry Bubba I took more than a half hour to write my post so didnt see yours. Bringing nvidia into the conversation though is not exactly relevant. Since, we know they had more issues with anyone with die shrinks including astronomically high fail rates. FAB difficulties or design??? No idea. I am not that smart. What I am saying is this is about CPU not GPUs. This is an AB conversation so C your way out.

(just an attempt at humour

if offended I can provide a 1-800 number for you to call , if it passes the filters. Seriously though, it was just a joke, it fit perfectly I could not resist, the 1-800 thing also a joke, relax, smoke something, but seriously this is a CPU discussion right? Completely different architecture. I do not see anyone in this thread complaining that 22nm SRAM is too high cost and has FAB failure issues.

In fact I dont see nVidia complaining about after their little snafu. If you linked to source not uploaded to imageshack you might get a more intelligent response.

).

).