- Joined

- Aug 20, 2023

Hi, i hope u can understand. Its my english + google translate. I know its not perfect, but the most interesting things r the pix. I prepared 142 pix. Now u can see the first 32 pictures and u will know some details behind the company, especially the start of LiquidExtasy. It will needs some days or weeks to translate text for 142 pictures.

Hello community,

If we start to talk about LiquidExtasywaterblocks, we have to start in the year of 2000, despite of the company started in 2008. In the year 2000 I had youth consecration and wanted to buy a water cooling system. I went to Jolly Joker Computershop, a local computer shop in my hometown, and asked for a quote on water cooling. They said it would be too expensive and its not worth. I went home disappointed. However, the water cooling issue has not died.

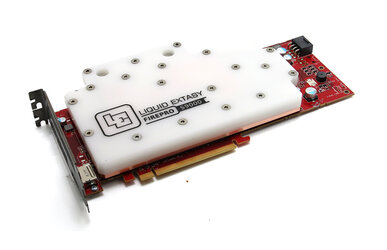

But the first of all a few words in advance. My name is Marc and I'm known in the communities as Al_, Al_Bundy and Teddito. The company started on 2008 and deals with the waterblocks. Later milling spindles and table tennis blades. So Custom-made waterblocks and table tennis blades are also possible for u. So that this service does not die, I need help from the community and platform. I can return some pictures and offers for the implementation of your custom builds and also experience in the field of CNC, table tennis and waterblocks. It is important to me that agreements are kept by both sides, although there may be delays in delivery for understandable reasons.

Corona, but also the Ukraine war is a challenge for many companies. Copper deliveries take up to 3 months, copper prices have tripled in some cases, it can no longer be delivered to every country as example through DHL especially also longer delivery routes ect. Pp. But I'm still here and have a right to exist because, as far as I know, there is no one who offers waterblocks for custom PCB's or realizes your custom builds easily and affordable against the submission of CAD files. Some users and small companies before me did that too, but unfortunately they are no longer active. I would be happy if I could enjoy similar permissiveness in the forum to be able to show my work.

I started my forums career in 2002 and have intensified waterblocks crafting threads since about 2007. Gradually everything has expanded and now you can order waterblocks for many exotic cards and boards. The company was founded in 2008 and production officially stopped in 2016 due my illness. Hopefully everything will be back to normal in next year so that everyone can have more fun with this project. However, this requires help from the community that honors the work and does not boycott it. If you do a lot, you sometimes make a mistake, that's completely normal. However, it is important that the errors are eliminated appropriately. If something went wrong, always write an email.

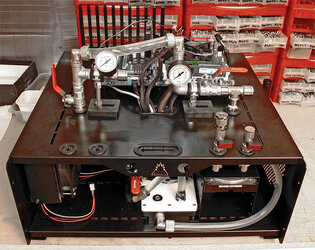

Unfortunately, since 2018 it hasn't been that easy to reward due to longer delivery times, which I didn't choose. It is well known that Liquidextasy is a onemanshow. If the protagonist is ill, nothing happens. If there is a broken cnc-machine, the productions stops. Or at least for a short time. Luckily I am now in a solid position with 3 cnc machines. Normally, a machine is always running if I'm not distracted by other activities. However, in the last few years, health has put a spanner in the works for me to start where I left off in 2017.

In the last 5 years I have invested around €60,000 in my health. Money that would have been used very good for the company... Unfortunately, my health improvement is very slow. Of course, it must broke bcoz I had an high pace and if u don’t care to urself and care just to ur company u will be sick…. But let's start with the history in 2002.

I started in 2002 and had a lot of things to do with copper and got various skills for copper processing. In 2004 I started building my first water cooling system, which I presented on Easy-mod.de at the time. The cooler got the name Al_Vis V1.

At that time there was a platform that tested waterblocks on a special benchtable ( with a FET not with a real CPU) and tested waterblocks of performance. -> Watercoolplanet.de I sent them some waterblocks, which didn't do badly for the first time. With the Al_Vis 1.4 I built a cooler that made it the 2nd place in the ranking. Coolers built with just a Dremel, driller and file. More coolers and reports in the forum followed and I received requests for replicas.

That's actually where it all started. I bought an HBM BF 20 Vario with studendsalery and earned some pocket money until I saved up a kit for the CNC.

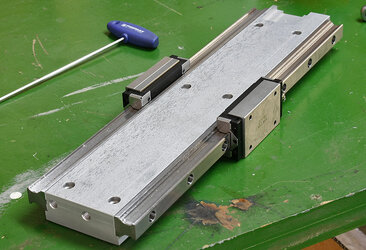

To get more skills in CNC I joyned Peters-cnc-ecke.de forum. When the modification to cnc-actions was finally finished, much more complex structures could be manufactured.

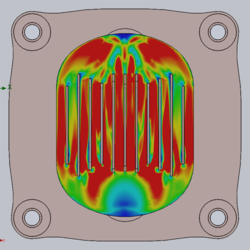

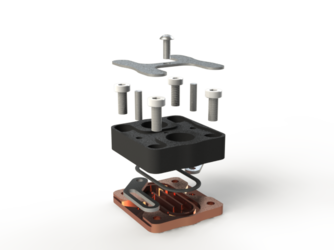

After my study was finished, the German goverment transferred me to civilian service, where I had prepared everything for founding the company in 2008. In the summer of 2008 the time had finally come and I had some support from a forum member in terms of CAD and CFD/FEM simulations. This is how the Narrowline CPU cooler came about and the company was founded under the Liquid Extasy label.

Then in 2009 Liquid Extasy got a reseller. Aquatuning. They helped me to sell the waterblocks. The first water coolers for graphics cards were also developed and sold via the online shop. For example for the Nvidia GTX 285

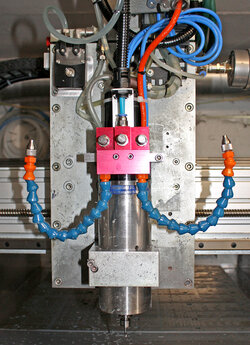

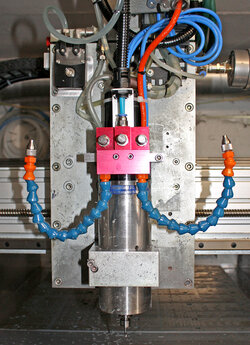

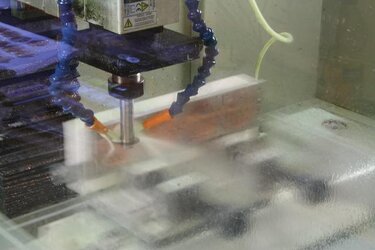

But the productiontime take too long time for me, I removed the original spindlemotor of the milling machine and replace it with a Kressspindle. From then on, higher feed rates are possible.

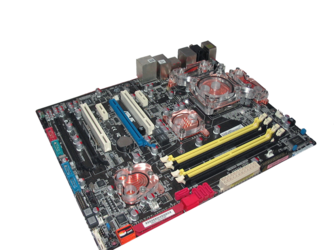

Other coolers quickly followed, for example the Asus P5Q and Nvidia's 8800GT.

In 2010 I changed the cooling structures of GPU coolers. -> HD 5870 waterblock. The cooler was created in cooperation with PC-Masters. Meanwhile, the interest was huge. I as a one manshow had released the most water coolers ever/year. Even the big ones like Aquacomputer and Watercool couldn't keep it up. 2010 was also the year I developed my first console water block. The Playstation 3 water cooler.

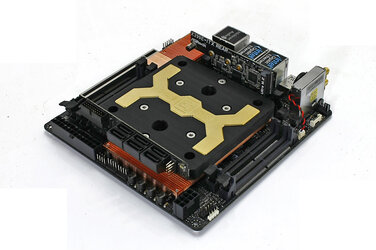

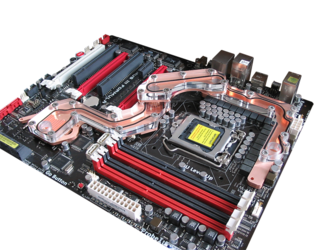

Since the Kress router regularly stopped working, I switched to a more expensive millingspindle. Suhner UAL23RF. This made it possible to produce faster. However, only 10 months. -> Bearings broken L. In 2010 the first fullcover waterblock for motherboards followed. The Asus Maximus III. Furthermore, In 2010 dealt first with the topic of nickel plating.

Meanwhile, I was also on the payroll at Alphacool. The clue was a universal waterblock for chipset and gpu’s. Alphacool sold thousands of Smart Motions . Unfortunately, the partnership did not last long because Alphacool closed the business at the time. Despite being the legal successor to Alphacool International, I had to forego the developer fee for the Smart Motion. So I modified the Smart Motion and released the VUCI. In retrospect, I should have sued Alphacool...

Later I started to offer windowcuts.

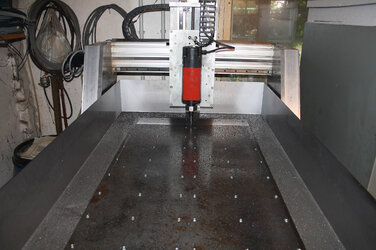

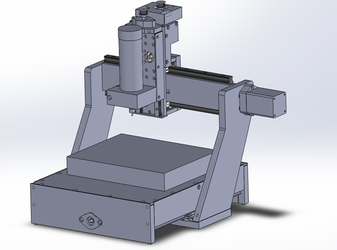

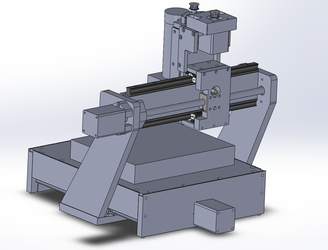

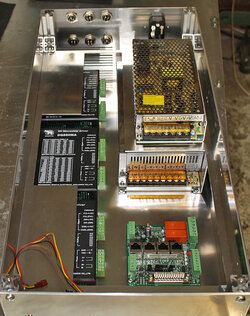

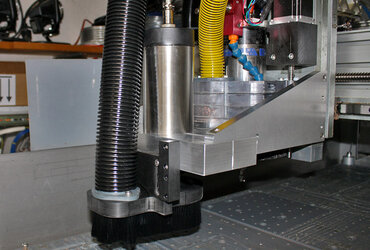

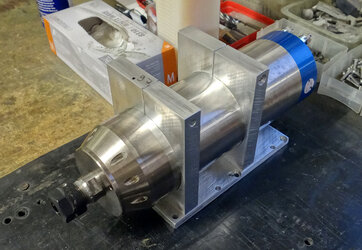

Since the Suhner millingspindle was broken again, I bought a real milling spindle and replaced the Suhner. For this purpose, the CNC was embedded in a housing which was also created in-house. Of course, with the foresight that something bigger should go into the cabin.

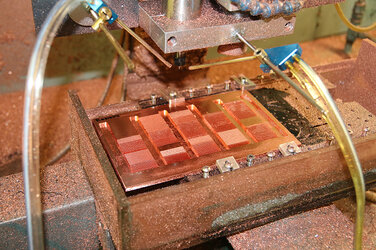

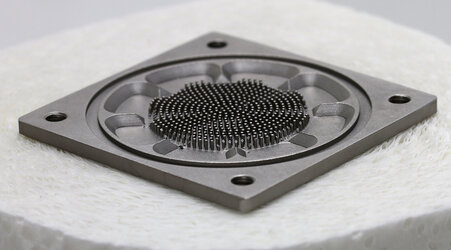

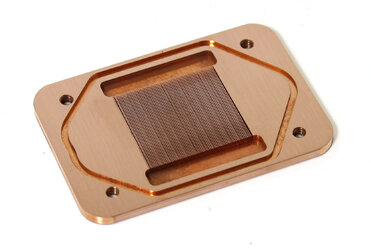

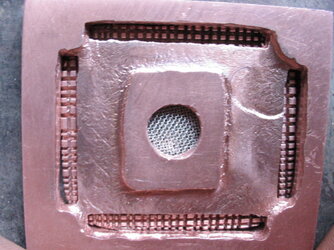

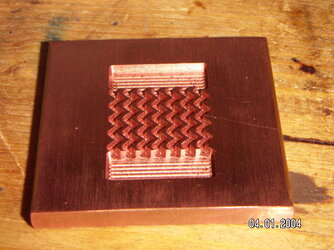

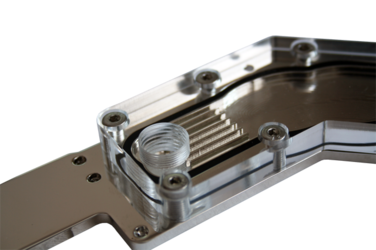

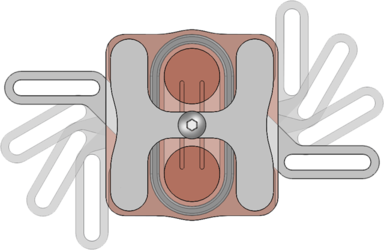

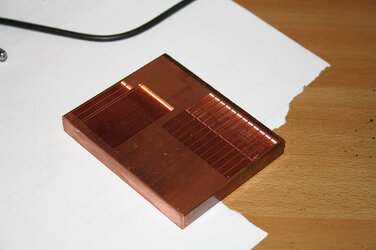

A little bit more was possible with this milling spindle. I was preparing for a small series for my friend. It was about a CPU waterblock that should be on the level of the usual waterblocks like Heatkiller and Kryos. I started slitting.

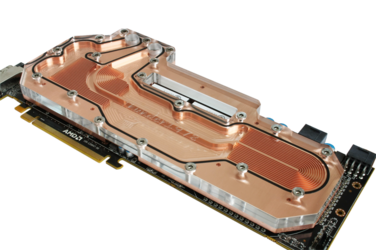

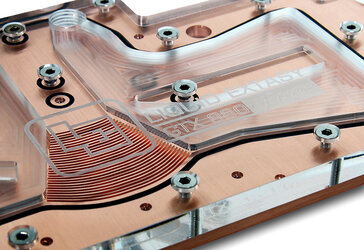

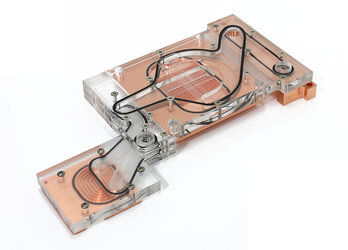

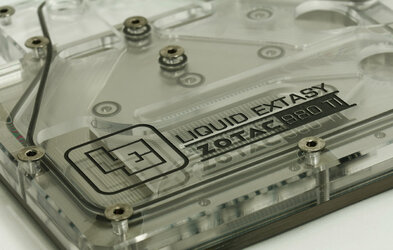

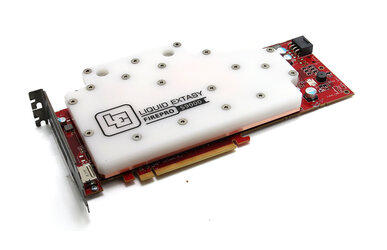

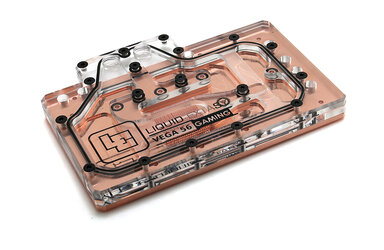

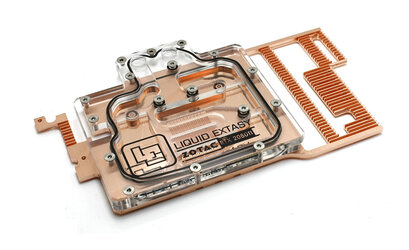

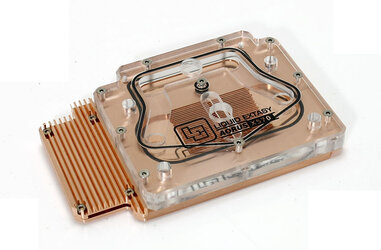

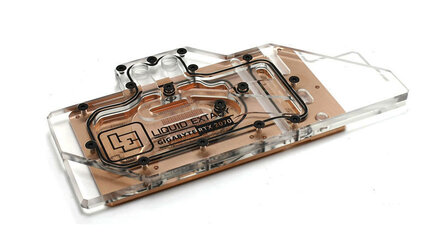

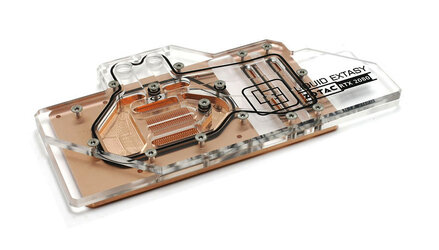

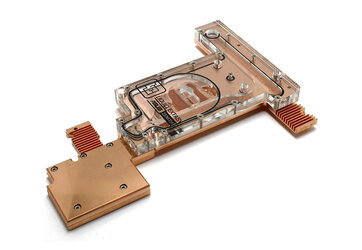

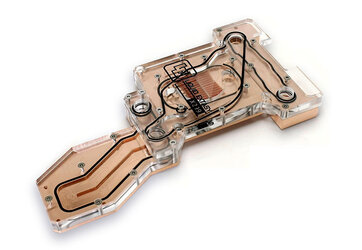

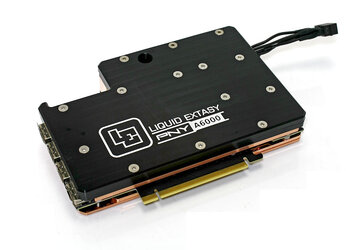

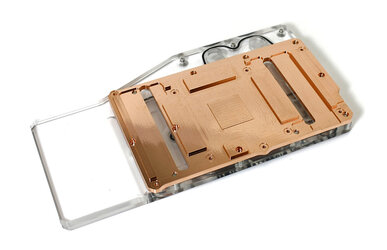

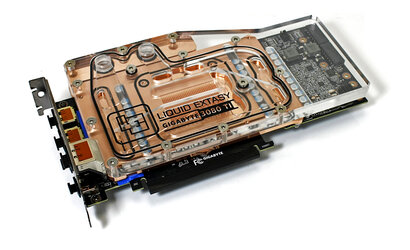

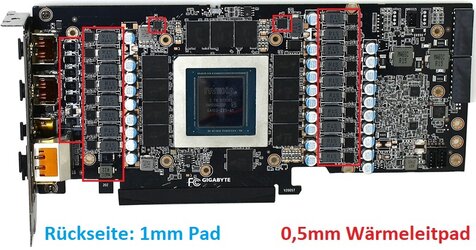

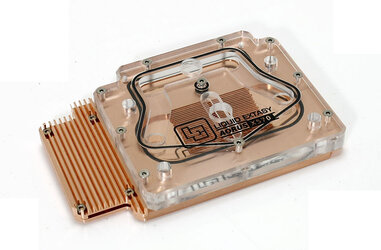

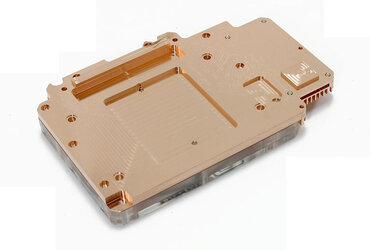

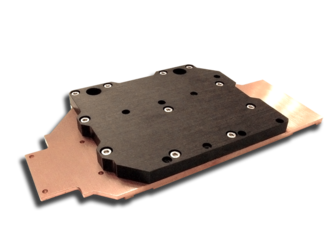

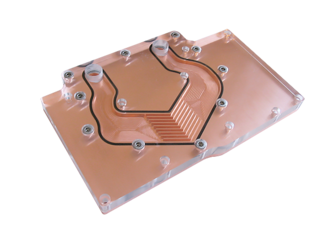

A current HD 6990 waterblock looks like this now. It is one of the cards with the highest TDP ever. A positive development of the cooler design should be noticeable

Hello community,

If we start to talk about LiquidExtasywaterblocks, we have to start in the year of 2000, despite of the company started in 2008. In the year 2000 I had youth consecration and wanted to buy a water cooling system. I went to Jolly Joker Computershop, a local computer shop in my hometown, and asked for a quote on water cooling. They said it would be too expensive and its not worth. I went home disappointed. However, the water cooling issue has not died.

But the first of all a few words in advance. My name is Marc and I'm known in the communities as Al_, Al_Bundy and Teddito. The company started on 2008 and deals with the waterblocks. Later milling spindles and table tennis blades. So Custom-made waterblocks and table tennis blades are also possible for u. So that this service does not die, I need help from the community and platform. I can return some pictures and offers for the implementation of your custom builds and also experience in the field of CNC, table tennis and waterblocks. It is important to me that agreements are kept by both sides, although there may be delays in delivery for understandable reasons.

Corona, but also the Ukraine war is a challenge for many companies. Copper deliveries take up to 3 months, copper prices have tripled in some cases, it can no longer be delivered to every country as example through DHL especially also longer delivery routes ect. Pp. But I'm still here and have a right to exist because, as far as I know, there is no one who offers waterblocks for custom PCB's or realizes your custom builds easily and affordable against the submission of CAD files. Some users and small companies before me did that too, but unfortunately they are no longer active. I would be happy if I could enjoy similar permissiveness in the forum to be able to show my work.

I started my forums career in 2002 and have intensified waterblocks crafting threads since about 2007. Gradually everything has expanded and now you can order waterblocks for many exotic cards and boards. The company was founded in 2008 and production officially stopped in 2016 due my illness. Hopefully everything will be back to normal in next year so that everyone can have more fun with this project. However, this requires help from the community that honors the work and does not boycott it. If you do a lot, you sometimes make a mistake, that's completely normal. However, it is important that the errors are eliminated appropriately. If something went wrong, always write an email.

Unfortunately, since 2018 it hasn't been that easy to reward due to longer delivery times, which I didn't choose. It is well known that Liquidextasy is a onemanshow. If the protagonist is ill, nothing happens. If there is a broken cnc-machine, the productions stops. Or at least for a short time. Luckily I am now in a solid position with 3 cnc machines. Normally, a machine is always running if I'm not distracted by other activities. However, in the last few years, health has put a spanner in the works for me to start where I left off in 2017.

In the last 5 years I have invested around €60,000 in my health. Money that would have been used very good for the company... Unfortunately, my health improvement is very slow. Of course, it must broke bcoz I had an high pace and if u don’t care to urself and care just to ur company u will be sick…. But let's start with the history in 2002.

I started in 2002 and had a lot of things to do with copper and got various skills for copper processing. In 2004 I started building my first water cooling system, which I presented on Easy-mod.de at the time. The cooler got the name Al_Vis V1.

At that time there was a platform that tested waterblocks on a special benchtable ( with a FET not with a real CPU) and tested waterblocks of performance. -> Watercoolplanet.de I sent them some waterblocks, which didn't do badly for the first time. With the Al_Vis 1.4 I built a cooler that made it the 2nd place in the ranking. Coolers built with just a Dremel, driller and file. More coolers and reports in the forum followed and I received requests for replicas.

That's actually where it all started. I bought an HBM BF 20 Vario with studendsalery and earned some pocket money until I saved up a kit for the CNC.

To get more skills in CNC I joyned Peters-cnc-ecke.de forum. When the modification to cnc-actions was finally finished, much more complex structures could be manufactured.

After my study was finished, the German goverment transferred me to civilian service, where I had prepared everything for founding the company in 2008. In the summer of 2008 the time had finally come and I had some support from a forum member in terms of CAD and CFD/FEM simulations. This is how the Narrowline CPU cooler came about and the company was founded under the Liquid Extasy label.

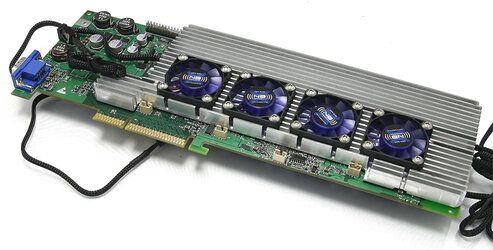

Then in 2009 Liquid Extasy got a reseller. Aquatuning. They helped me to sell the waterblocks. The first water coolers for graphics cards were also developed and sold via the online shop. For example for the Nvidia GTX 285

But the productiontime take too long time for me, I removed the original spindlemotor of the milling machine and replace it with a Kressspindle. From then on, higher feed rates are possible.

Other coolers quickly followed, for example the Asus P5Q and Nvidia's 8800GT.

In 2010 I changed the cooling structures of GPU coolers. -> HD 5870 waterblock. The cooler was created in cooperation with PC-Masters. Meanwhile, the interest was huge. I as a one manshow had released the most water coolers ever/year. Even the big ones like Aquacomputer and Watercool couldn't keep it up. 2010 was also the year I developed my first console water block. The Playstation 3 water cooler.

Since the Kress router regularly stopped working, I switched to a more expensive millingspindle. Suhner UAL23RF. This made it possible to produce faster. However, only 10 months. -> Bearings broken L. In 2010 the first fullcover waterblock for motherboards followed. The Asus Maximus III. Furthermore, In 2010 dealt first with the topic of nickel plating.

Meanwhile, I was also on the payroll at Alphacool. The clue was a universal waterblock for chipset and gpu’s. Alphacool sold thousands of Smart Motions . Unfortunately, the partnership did not last long because Alphacool closed the business at the time. Despite being the legal successor to Alphacool International, I had to forego the developer fee for the Smart Motion. So I modified the Smart Motion and released the VUCI. In retrospect, I should have sued Alphacool...

Later I started to offer windowcuts.

Since the Suhner millingspindle was broken again, I bought a real milling spindle and replaced the Suhner. For this purpose, the CNC was embedded in a housing which was also created in-house. Of course, with the foresight that something bigger should go into the cabin.

A little bit more was possible with this milling spindle. I was preparing for a small series for my friend. It was about a CPU waterblock that should be on the level of the usual waterblocks like Heatkiller and Kryos. I started slitting.

A current HD 6990 waterblock looks like this now. It is one of the cards with the highest TDP ever. A positive development of the cooler design should be noticeable