-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dice Tubes

- Thread starter Son1990

- Start date

- Joined

- Jul 13, 2003

- Location

- Montréal, PQ, Canada.

How are you planning on mounting the GPU tube?

Looks pretty good man .

.

Looks pretty good man

- Joined

- Jul 13, 2003

- Location

- Montréal, PQ, Canada.

Son1990 said:Pics of that will follow shortly. CPU will be attached via custom made wooden bracket.

CPU is easy

- Joined

- May 23, 2001

- Location

- Asteroid B-612

The GPU container base is drilled and will be tapped soon for metric2 bolts. These containers were designed with low material costs in mind, but without having to compromise on using aluminum.

- Joined

- Jul 13, 2003

- Location

- Montréal, PQ, Canada.

Captain Slug said:The GPU container base is drilled and will be tapped soon for metric2 bolts. These containers were designed with low material costs in mind, but without having to compromise on using aluminum.

Thats what I wanted to know, from looking at the pic I couldnt see any holes in the base of the GPU container. The base looked to big to fit within the mounting points on a card, so you can understand my confusion.

How are you planning on insulating the area that outside the shim that is covered by the base plate (I dont know if that makes sense). There will be a "gap" between the outside insulation and the core/shim of the card right? Are you just going to use a face peice of insulation around the shim and just compress it with the base of the tube?

Looks like some very nice tubes, pretty much exactly how I was planning on building mine Slug.

I cant wait to see some runs with these babies Son

- Joined

- May 23, 2001

- Location

- Asteroid B-612

Insulating it should end up being the same process as other containers. Just alot of sandwhich layers glued together. And obviously the backside of the video card will also need insulation.

And the mounting holes for both the FX and Radeon series land within the 2"x3" size of the GPU container base and outside of the 2" outer diameter tube so the base is threaded all of the way through for mounting with M2 bolts.

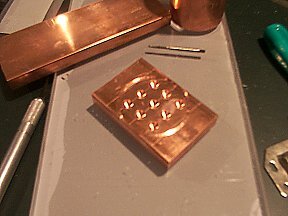

Here's a crappy photo of the varied depth hole pattern that's inside both containers.

Newer revisions of the container design will have a different pattern in a smaller size.

And the mounting holes for both the FX and Radeon series land within the 2"x3" size of the GPU container base and outside of the 2" outer diameter tube so the base is threaded all of the way through for mounting with M2 bolts.

Here's a crappy photo of the varied depth hole pattern that's inside both containers.

Newer revisions of the container design will have a different pattern in a smaller size.

- Joined

- Jul 13, 2003

- Location

- Montréal, PQ, Canada.

Looks good slug, I am glad you started focusing some of your skills on cooling applications now as well.

I think I might have to pick up a tap and die set myself for when I make my own tubes. Taping the GPU tube does make mounting a lot easier rather than trying to get a hold down plate onto the tube itself.

The base on the GPU tube looks a LOT thicker than the base on the CPU tube. Was the CPU tube just made before and then you sourced some nice thick stock? Or was there a reason behind this?

I think I might have to pick up a tap and die set myself for when I make my own tubes. Taping the GPU tube does make mounting a lot easier rather than trying to get a hold down plate onto the tube itself.

The base on the GPU tube looks a LOT thicker than the base on the CPU tube. Was the CPU tube just made before and then you sourced some nice thick stock? Or was there a reason behind this?

- Joined

- May 23, 2001

- Location

- Asteroid B-612

Both bases are the same thickness and cut from the same 1/2"t bar.

- Joined

- Dec 20, 2001

It looks soldered together. Is that the case?

If so it really needs to be brazed.

If so it really needs to be brazed.

- Joined

- May 23, 2001

- Location

- Asteroid B-612

Yes it is, but silver solder was used and it will hold fine since there are no butt joints.{PMS}fishy said:It looks soldered together. Is that the case?

If so it really needs to be brazed.

- Joined

- May 11, 2004

- Location

- Montana tech Butte mt.

Captain Slug said:Yes it is, but silver solder was used and it will hold fine since there are no butt joints.

Thats not what the problem is the problem with soldering is solder joints are more prone to cracking when cold becuase of how soldering works compared to brazing.

I am saying it will probably not but hey I have seen soldered conduit joints crack and let water into a $1000 peice of solid conduit at radio transmitter sites becuase they were exposed to -20+°c temps for a fair amount of time.

- Joined

- May 23, 2001

- Location

- Asteroid B-612

Yeah, the shop owner makes pressure containers and he helped me make the soldering joints on the base so that expansion/contraction won't be as much of an issue. The copper pipe segment is hammered into a groove that was cut into the base using a custom bit in circle cutter and was tested to be leak proof even without the solder.

The brass tube that's inserted into the copper pipe was fluted at the end before being inserted and soldered.

The silver solder on the CPU container is acting more as a glue and filler than it is as a seal. The GPU container on the other hand is a different issue.

I'm sure it would be a much larger concern if this were a phase change setup. We were kind of pressed for time and for future containers I'll need some practice in order for brazing to be possible.

The brass tube that's inserted into the copper pipe was fluted at the end before being inserted and soldered.

The silver solder on the CPU container is acting more as a glue and filler than it is as a seal. The GPU container on the other hand is a different issue.

I'm sure it would be a much larger concern if this were a phase change setup. We were kind of pressed for time and for future containers I'll need some practice in order for brazing to be possible.

- Joined

- Dec 20, 2001

-aDaM^ said:Ya, youll need oxy/acelene setup for brazing.

No you don't.

- Joined

- Dec 8, 2005

{PMS}fishy said:No you don't.

He's saying that oxy/acelene is overkill. ($$$ wise)

Similar threads

- Replies

- 51

- Views

- 1K

- Replies

- 2

- Views

- 643