- Joined

- Nov 12, 2002

- Location

- Rootstown, OH

I know a lot of design stuff and home made pots/evaporators are being done across the hardware community, but I haven't ever gone looking for it. If you have, or if you want to help me look, I could use your help.

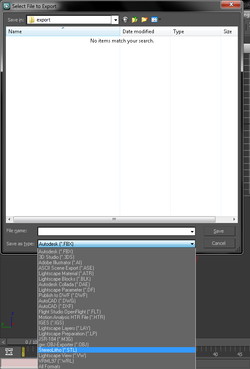

I'm interested in having my own pot/evaporator milled. I want to take any information I can find on the net, and anything we can infer or learn from existing commercial designs, and then I'll figure out exactly what I want to have milled. Once we compile some reference material, I'm going to put together some dimensions, state some guidelines, list desirable features, then recruit some people from the forums who can do autocad/solidworks stuff as prototypes, which we can tweak and I'll then hand it off to the people who will create it.

Anything contributed in the replies below, I'll compile into this first post, and possibly use as an article on the frontpage where I'll solicit further input from our readers. I'll be doing my own looking around also and I'll reply below with my own findings also.

Ultimately, my goal is to avoid the drawbacks of commercial designs (they are designed to be good, and be economical to produce/sell), and have an "open" community designed pot/evaporator that anyone can take to the mill and create for themselves.

Fundamental values (suggest additions to this list):

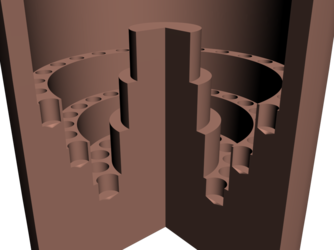

1. Higher mass stabilizes temp swings

2. Reasonable size/dimensions around socket eases insulation and reduces likelihood of interfering with socket area caps on some boards

3. Solid copper eliminates concerns of interfacing between copper base/aluminum upper

4. Increased internal base surface area helps pull down temps, uses LN2 more efficiently

5. Mounting hardware for present/future AMD/Intel sockets

Links/References:

1. ?

2. ?

3. ?

Useful Specifications:

1. Dimensions for hold down brackets

775 is 72mm square (center to center)

1366 is 80mm square

I'm interested in having my own pot/evaporator milled. I want to take any information I can find on the net, and anything we can infer or learn from existing commercial designs, and then I'll figure out exactly what I want to have milled. Once we compile some reference material, I'm going to put together some dimensions, state some guidelines, list desirable features, then recruit some people from the forums who can do autocad/solidworks stuff as prototypes, which we can tweak and I'll then hand it off to the people who will create it.

Anything contributed in the replies below, I'll compile into this first post, and possibly use as an article on the frontpage where I'll solicit further input from our readers. I'll be doing my own looking around also and I'll reply below with my own findings also.

Ultimately, my goal is to avoid the drawbacks of commercial designs (they are designed to be good, and be economical to produce/sell), and have an "open" community designed pot/evaporator that anyone can take to the mill and create for themselves.

Fundamental values (suggest additions to this list):

1. Higher mass stabilizes temp swings

2. Reasonable size/dimensions around socket eases insulation and reduces likelihood of interfering with socket area caps on some boards

3. Solid copper eliminates concerns of interfacing between copper base/aluminum upper

4. Increased internal base surface area helps pull down temps, uses LN2 more efficiently

5. Mounting hardware for present/future AMD/Intel sockets

Links/References:

1. ?

2. ?

3. ?

Useful Specifications:

1. Dimensions for hold down brackets

775 is 72mm square (center to center)

1366 is 80mm square

Last edited:

Did I copy it exactly, but in a round tube?

Did I copy it exactly, but in a round tube?