- Joined

- Mar 14, 2013

- Location

- Massachusetts

- Thread Starter

- #21

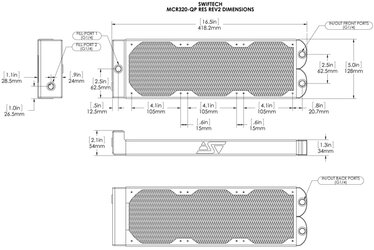

You SURE the rad you have has for the fill port G1/4 threads?

Judging from these specs, yes. However, now that I think about it I don't want to get the fill port. I want to get an additional compression fitting. I'll just get one more of the same one that came with my kit. I just tried screwing one into the fill port and fit fine.

For the fill port on the rad/res...

http://www.swiftech.com/1-2x3-4inch-LokSeal-Compression-fitting.aspx

Then some of my extra tubing that came with my kit.

To plug the top of the tubing...

http://www.swiftech.com/12inbarb-remote-fill-port.aspx

My goal is to minimize the risk of spilling into the case.