- Joined

- Mar 14, 2013

- Location

- Massachusetts

Well the time has come to begin my first legit water cooling build. I'll be doing this over the next few days as I don't feel like rushing and want to take my time to ensure perfection. Hopefully I haven't screwed anything up yet

First few notes and questions...

---The Swiftech packaging was great. No issues there. Tons of packaging peanuts and everything in their own inner box. No complaints in any way.

---I cleaned the whole length of tubing while waiting for the water to boil. Cleaned the tubing with hot water and a little bit of dish soap and thoroughly rinsed again. Going to rinse again with distilled.

---Something I was not expecting on the rad is that the screws that come in place where the tubing goes are not strong screws. It seems they do this as you are going to remove them for the compression fittings anyway. Just little place holder plastic screws so stuff doesn't get into the rad. What this caused is water so splash around a decent amount when cleaning the rad. Got some on the fins so hopefully that isn't a problem.

---A couple fins were slightly bent in the process. Nothing major, but I just bent them back into place. I do need to be more careful with this though.

---Went through the cleaning process. I was actually surprised how clean the rad was straight out of the box. No debris at all really, however I still went through the steps in the sticky to ensure. Going to do one more rinse through with distilled water to be triple sure.

---Because in my kit the pump and block are one unit, what would be the best cleaning method for this? In the sticky it says do not open the block, but it says open the pump and rinse? Ideas?

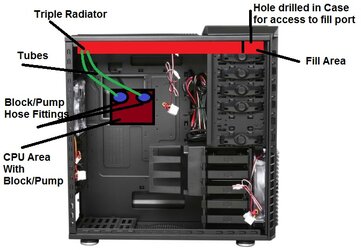

Once I do my final rinse I will let the rad dry and I will begin the planning stages. I have a very solid idea of what I am going to, I plan on posting an image of my idealized layout shortly to get some opinions.

Stay tuned for before pictures and gear pictures.

First few notes and questions...

---The Swiftech packaging was great. No issues there. Tons of packaging peanuts and everything in their own inner box. No complaints in any way.

---I cleaned the whole length of tubing while waiting for the water to boil. Cleaned the tubing with hot water and a little bit of dish soap and thoroughly rinsed again. Going to rinse again with distilled.

---Something I was not expecting on the rad is that the screws that come in place where the tubing goes are not strong screws. It seems they do this as you are going to remove them for the compression fittings anyway. Just little place holder plastic screws so stuff doesn't get into the rad. What this caused is water so splash around a decent amount when cleaning the rad. Got some on the fins so hopefully that isn't a problem.

---A couple fins were slightly bent in the process. Nothing major, but I just bent them back into place. I do need to be more careful with this though.

---Went through the cleaning process. I was actually surprised how clean the rad was straight out of the box. No debris at all really, however I still went through the steps in the sticky to ensure. Going to do one more rinse through with distilled water to be triple sure.

---Because in my kit the pump and block are one unit, what would be the best cleaning method for this? In the sticky it says do not open the block, but it says open the pump and rinse? Ideas?

Once I do my final rinse I will let the rad dry and I will begin the planning stages. I have a very solid idea of what I am going to, I plan on posting an image of my idealized layout shortly to get some opinions.

Stay tuned for before pictures and gear pictures.