- Joined

- Dec 28, 2004

- Location

- Canada, BC, Gibsons

Well I finally got all the parts I ever needed! So now it is time to BUILD! (Please keep in mind I don’t give a squat about super low temps, I’ll be happy to hold a nice +-0C constant, in fact that is my main goal is to simply keep it at a nice cool +-0C and perhaps for fun lower if I feel the need. So please no bashing or ranting at how it won’t get Über cold, I all ready know this nor do I care!)

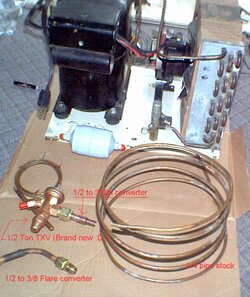

Here's the parts list:

- Copland R-12 Medium temp compressor

- 1/2 Ton TXV American control Company

- Sporlan 1/4SAE Flare, Solenoid Valve (NC) <Got one

- Sporlan Filter/Dryer <Got one

- Sporlan Sight Glass <Got one

- Ranco Low pressure trigger <Got one

- Home made receiver <Scored a free one and bought one

Tubing Size:

- 3/8th

- 1/4th

Evaporator:

- Helically wound 3/8th Tubing

Refrigerant:

- An Azeotropic Mix of 80/20% by Mass weight of R-134a & R-600a (This is said to out perform R-12, and is Listed as a drop in replacement) < May just use Pur R-134

History:

This all started when I found an old vending machine, before that point I was all ways interested in phase change, and I managed to pull the plant out of it, this finally gave me a chance to mess around with the idea. Well years later and TONs of learning I slowly started to collect parts and plot a killer build, well due to a good friend and some luck I got all I needed and being I run a Dual Xeon server what better project then to chill it!

OPERATION:

Obviously it will be pointless if I have to sit there and flick a switch one and off and it would all so be murder to the hydro to leave it running all the time! So how do I get it to cool well yet not short cycle or run 24/7?

The solution? Copy a large-scale systems way of doing it! not creative in of its self but very clever way to deal with the issue at hand non the less

Lets start at the solenoid valve, When the water gets too warm the thermostat makes a call to the Normally-Closed Valve telling it to open, this will allow liquid refrigerant rush into the TXV, the TXV then meters the refrigerant to the needed level to keep the evaporator at a constant temp.

This whole operation starts very fast, but wait! The compressor isn't running at this point! The thermostat only told the solenoid valve to open

this is where the low side trigger comes in, it sees the sudden rise on the low side and then tells the compressor to turn on! The system will run until the thermostat is happy again at which point it shuts of the solenoid valve and the suction vacuum will increase to the cut off point of the low side switch (This is because even though the thermostat shut of the valve, the compressor is still running).

The reason for this is better efficiency from the refrigeration system, any leaked refrigerant during the off cycle will evaporate raising suction pressure to the trigger point, at which the system will pump down and, while at it, further chill the water without needing a full out cycle and negate the need of an accumulator...

Work to do & Don:

So fare I need to build a Receiver, and to figure out final wiring. I have the low-pressure switch connected to a homemade L bracket and wired to the compressor.

The main thing on my list though is to get the compressor flushed & refilled with clean mineral oil as the old oil was beyond salvage. I have fabricated a ½ SAE Flare to 3/8th Copper solder connecter for the TXV to Evaporator mount.

My goal for now is to finish the Compressor Plant and have it fully oiled and wired and at a running state before I start making the evaporator. Aside from needing a couple things, yet to arrive, in the mail this is nearly complete unless I should need to replace the high side service valve as I fear I may well need to do!

Real picks soon to follow, but for now I nice MS-Paint on to hold you through!

http://img114.imageshack.us/my.php?image=compressorplant4kc.jpg

All items in BOLD have been updated as of Jun 6th 2006 (And satan hasn't poped up any where yet )

)

Here's the parts list:

- Copland R-12 Medium temp compressor

- 1/2 Ton TXV American control Company

- Sporlan 1/4SAE Flare, Solenoid Valve (NC) <Got one

- Sporlan Filter/Dryer <Got one

- Sporlan Sight Glass <Got one

- Ranco Low pressure trigger <Got one

- Home made receiver <Scored a free one and bought one

Tubing Size:

- 3/8th

- 1/4th

Evaporator:

- Helically wound 3/8th Tubing

Refrigerant:

- An Azeotropic Mix of 80/20% by Mass weight of R-134a & R-600a (This is said to out perform R-12, and is Listed as a drop in replacement) < May just use Pur R-134

History:

This all started when I found an old vending machine, before that point I was all ways interested in phase change, and I managed to pull the plant out of it, this finally gave me a chance to mess around with the idea. Well years later and TONs of learning I slowly started to collect parts and plot a killer build, well due to a good friend and some luck I got all I needed and being I run a Dual Xeon server what better project then to chill it!

OPERATION:

Obviously it will be pointless if I have to sit there and flick a switch one and off and it would all so be murder to the hydro to leave it running all the time! So how do I get it to cool well yet not short cycle or run 24/7?

The solution? Copy a large-scale systems way of doing it! not creative in of its self but very clever way to deal with the issue at hand non the less

Lets start at the solenoid valve, When the water gets too warm the thermostat makes a call to the Normally-Closed Valve telling it to open, this will allow liquid refrigerant rush into the TXV, the TXV then meters the refrigerant to the needed level to keep the evaporator at a constant temp.

This whole operation starts very fast, but wait! The compressor isn't running at this point! The thermostat only told the solenoid valve to open

this is where the low side trigger comes in, it sees the sudden rise on the low side and then tells the compressor to turn on! The system will run until the thermostat is happy again at which point it shuts of the solenoid valve and the suction vacuum will increase to the cut off point of the low side switch (This is because even though the thermostat shut of the valve, the compressor is still running).

The reason for this is better efficiency from the refrigeration system, any leaked refrigerant during the off cycle will evaporate raising suction pressure to the trigger point, at which the system will pump down and, while at it, further chill the water without needing a full out cycle and negate the need of an accumulator...

Work to do & Don:

So fare I need to build a Receiver, and to figure out final wiring. I have the low-pressure switch connected to a homemade L bracket and wired to the compressor.

The main thing on my list though is to get the compressor flushed & refilled with clean mineral oil as the old oil was beyond salvage. I have fabricated a ½ SAE Flare to 3/8th Copper solder connecter for the TXV to Evaporator mount.

My goal for now is to finish the Compressor Plant and have it fully oiled and wired and at a running state before I start making the evaporator. Aside from needing a couple things, yet to arrive, in the mail this is nearly complete unless I should need to replace the high side service valve as I fear I may well need to do!

Real picks soon to follow, but for now I nice MS-Paint on to hold you through!

http://img114.imageshack.us/my.php?image=compressorplant4kc.jpg

All items in BOLD have been updated as of Jun 6th 2006 (And satan hasn't poped up any where yet

Last edited: