My reasoning for using a forged part (manufactured by Intricast) is based on several reasons:

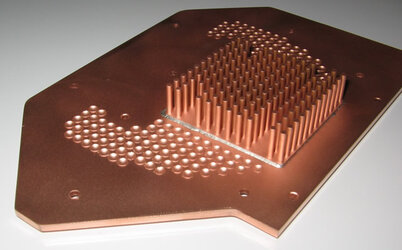

-Achieve maximum cooling surface area, utilizing a pin pattern not machineable by conventional methods.

-Create a part with as thin a base as possible while still maintaining tight tolerances.

-Avoid the excess "girth" typical of machined, full cover waterblocks without sacrifcing cooling capacity.

Additionally, by utilizing this strategy of using a insert seperate from the base, it can be hand lapped to 5 microns, something that cannot be achieved from a one piece design due to the difference in height between the GPU contact plane and the RAM contact plane.

The end result is a full cover block that outperforms all competing solutions while weighing as little as half as much. Using the forged pin array insert allows for exponentially more cooling surface area where it's needed, along with a thinner base (a key for watercooling performance) accross all planes.

As for the manufacturing methods employed when forged components are not used, an arbor of ganged slither saws making two angled passes is the most common means. However, as we've seen of late with Swiftech's Apogee parts, the residual mess of shavings and burrs resulting from the cutting process is less than desirable.

How can I guarantee it doesn't leak? By applying aggressive flux and premium silver solder to the surfaces prior to annealing the two components in a furnace.

This process bonds the two copper components at a molecular level - and the gap it is filling is about 1/100th of an inch as each components is machined and deburred prior to the procedure.