Well Just got me self an MCP600 from a gent,,, on this very forum; this will go in the liquid side of the system (Kinda goes with out saying lol).

I may build in a res to the chiller cell hard piped as an air trap, or put in a purge valve to let it out manually during filling. There is a leak in the chiller cell that I'm trying to locate, so by filling it then locating the leak will be easy.

The next build will be a 6,000BTU/hr system again but much more well engineered. This current system more evolved then it was designed hence the very high cost of raw materials and the slow build, but it gave me a chance to re-sharpen my fabricating skills while I put into practise the stuff I have learnt in refrigeration. Another unique thing I'll do with the next build is the compressor will be water cooled its self via a small bleed off from the return water.

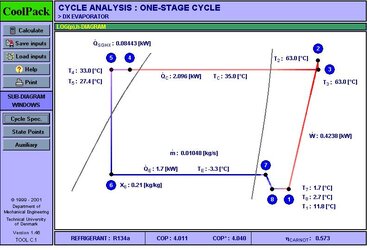

But for now the current project is on hold till the pump arrives, I may put the MCP600 to use in my current WC loop and take the MCP650 and put it to work in the chiller unit as noise will not be an issue there, and since the system designed operating temp is only -3.3C out 0C in there should be no issues with the temp at the pump due to its placement at the water return line.